US NAVY COMBAT VESSELS

(Actual Client)

MEGA YACHT ASTRA

(Actual Client)

NYC HORNBLOWER INFINITY

(Actual Client)

PORT OF LONG BEACH FIRE DEPT

(Actual Client)

OLIVER HAZARD PERRY

(Actual Client)

Previous slide

Next slide

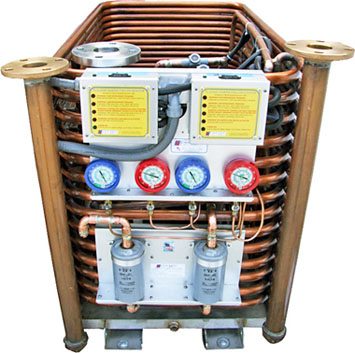

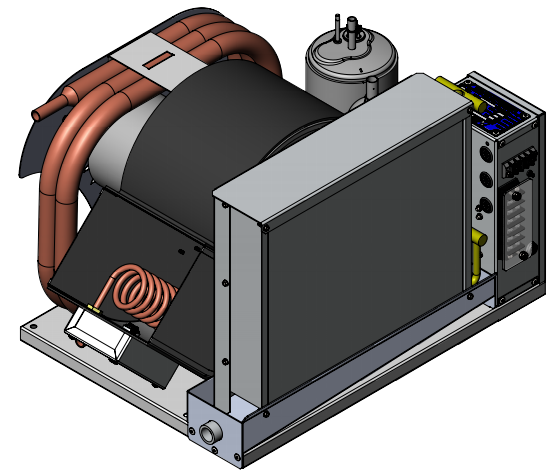

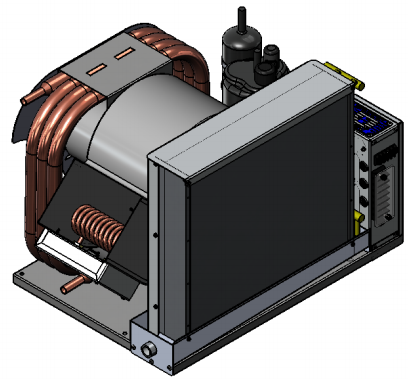

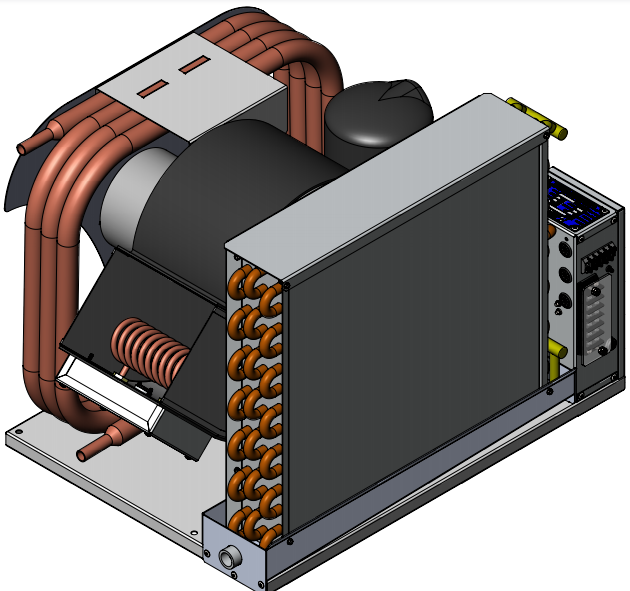

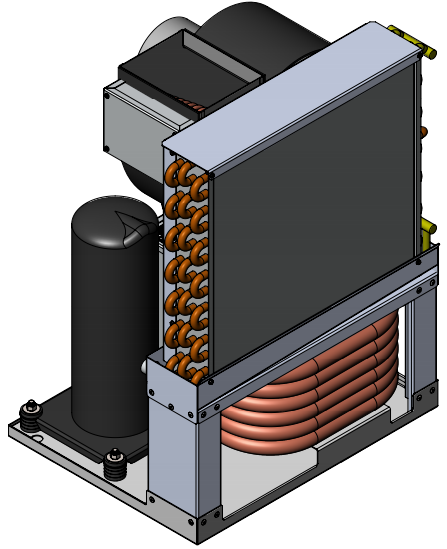

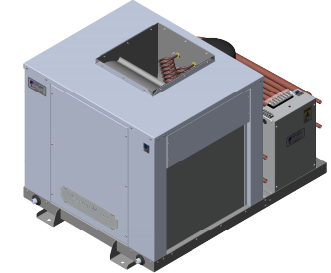

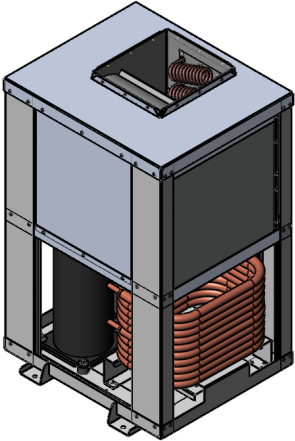

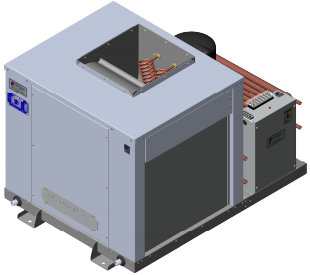

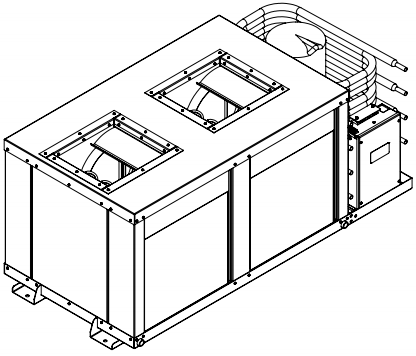

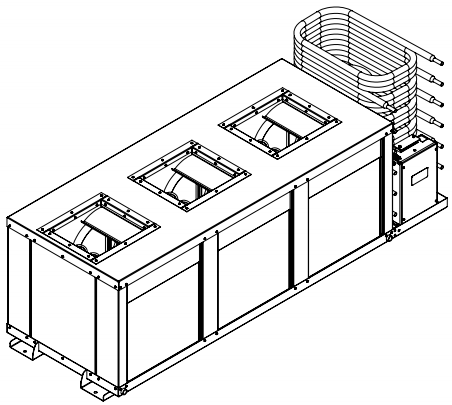

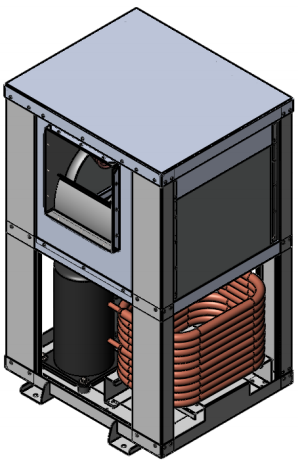

Manufacturer of

Marine Air Conditioning Systems

for the Recreational, Commercial and Military Industries

Since 1995

Manufactured with pride in the USA

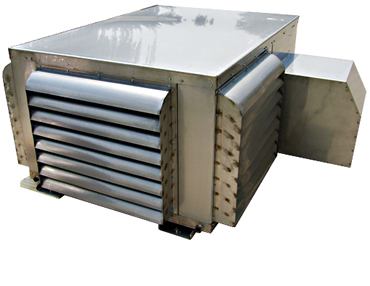

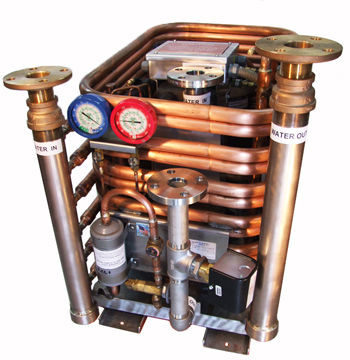

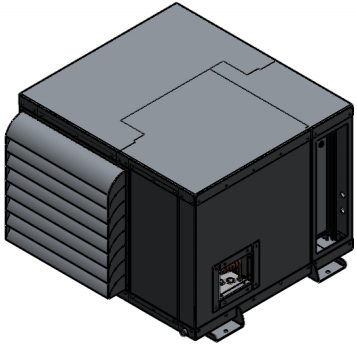

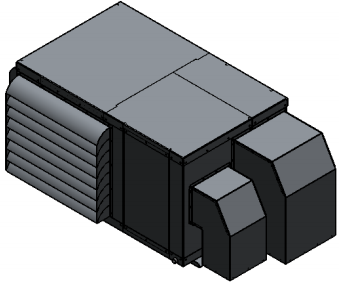

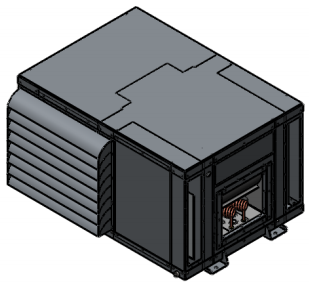

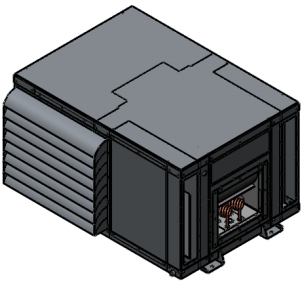

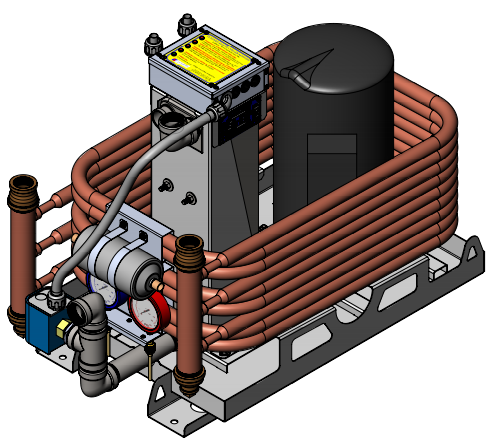

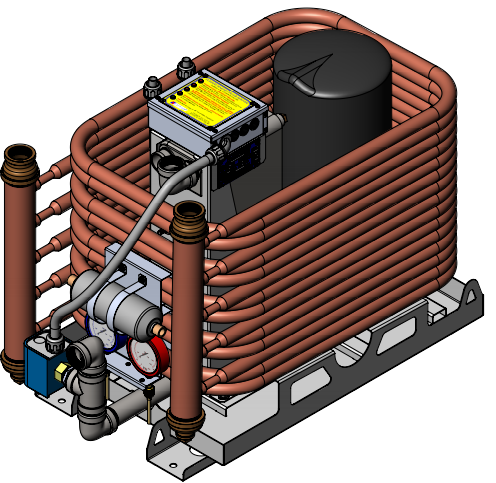

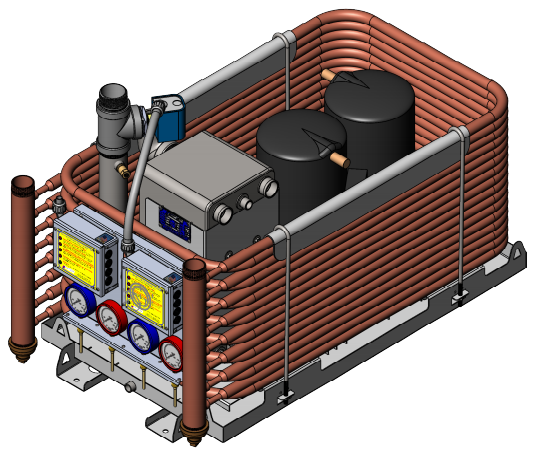

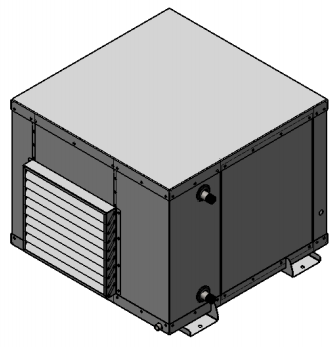

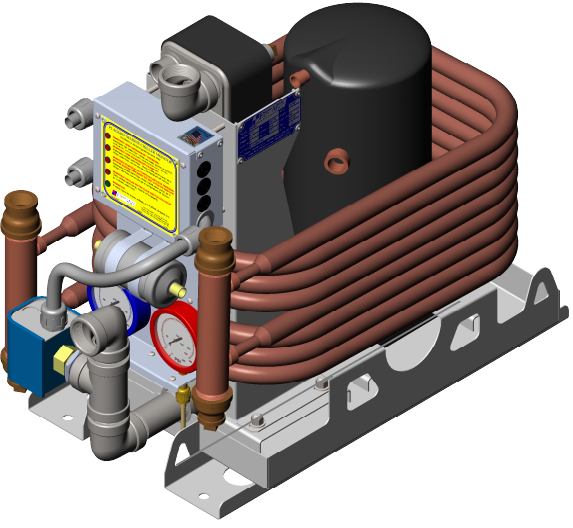

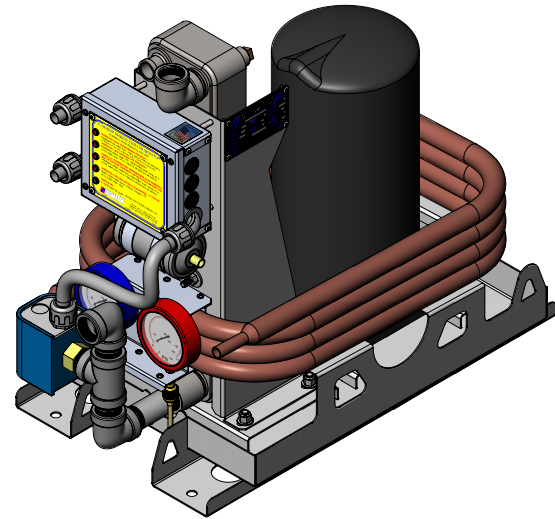

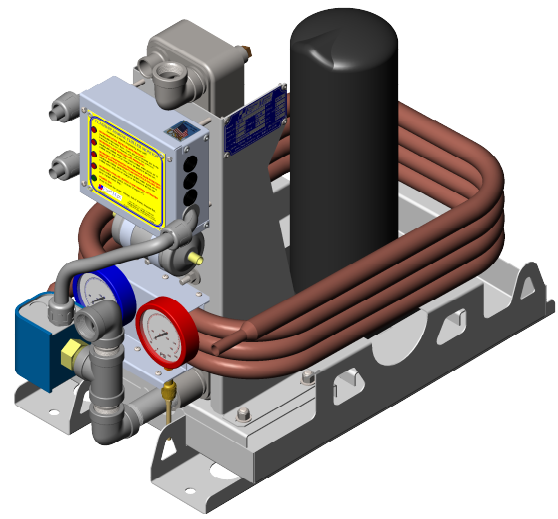

FLAGSHIP MARINE AIR CONDITIONING SYSTEMS

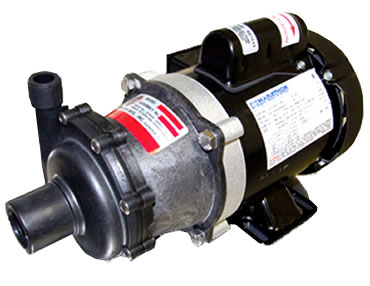

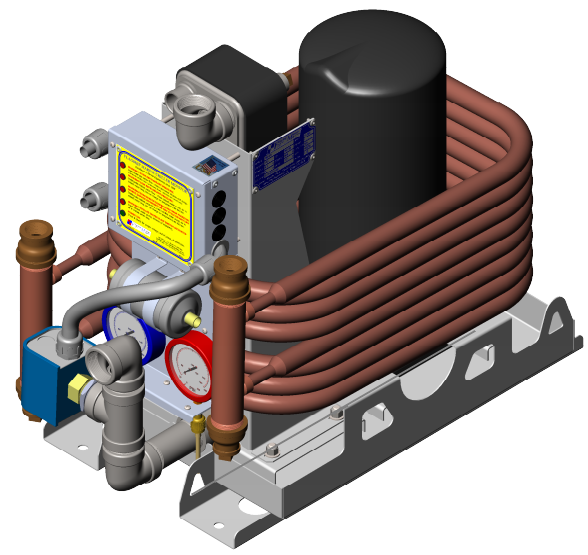

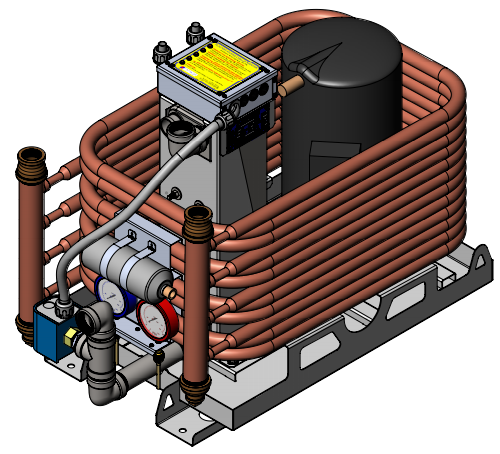

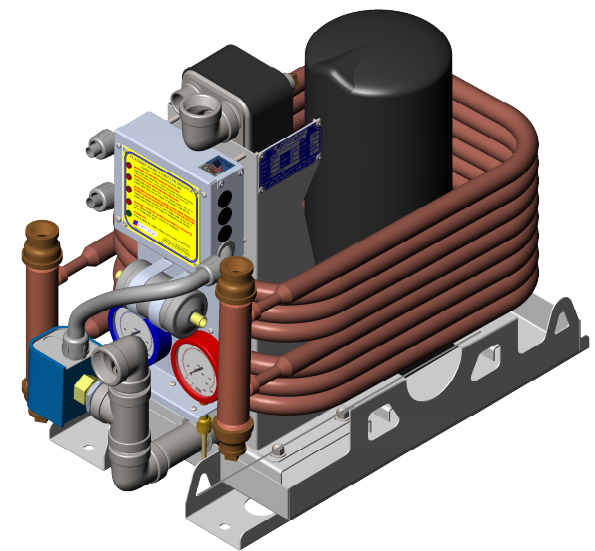

OUR FLAGSHIP ACCESSORIES & PUMPS

State Of The Art Marine Air Conditioning Units

Made ONLY with DOMESTIC Alloys

We Offer Affordable Factory Direct Pricing

Call Now 1-800-316-6426