The two typical means of producing heat in marine HVAC units are resistive electric and reverse cycle. Although we can and have manufactured both types, we normally stock and sell the resistive electric for many different reasons which we will outline on this page.

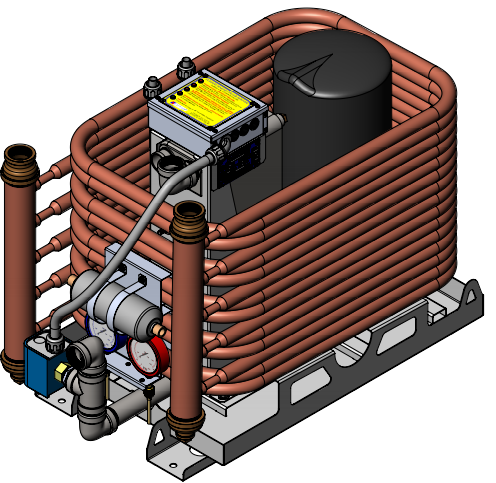

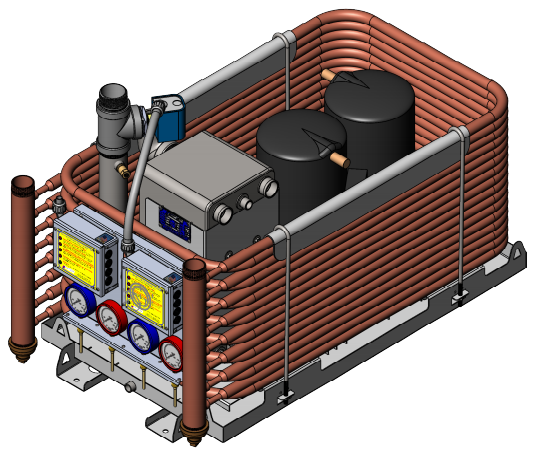

With a reverse cycle heating system, a reversing valve reverses the flow of refrigerant, making the condenser an evaporator and the evaporator a condenser. We will outline the benefits of each system for your consideration.

| Benefits Of Reverse Cycle Heat: | Benefits Of Electric Resistive Heat: |

|---|---|

| Reverse cycle systems are a more efficient means of producing heat when compared to resistive electric heat. • In domestic applications these systems can save | Extended component life. You are not using the compressor and raw water pump for heat. The only moving part is the blower. |

| In domestic applications these systems can save homeowners thousands of dollars/year in electric bills when compared to electric heat, however the initial cost can be significant in colder climates where underground heat sinks are required. | Electric heat units will work ANYWHERE – not dependent on water temperature. Reverse cycle heat will not work with a raw water temperature below about 45-50°F and the compressor is stressed near these temperatures. The standard 2KW element we have on our 16,500 BTU units are presently used on craft from Alaska, The Great Lakes and Maine to the Gulf Coast and Virgin Islands. |

| In marine applications if you are a live aboard with metered electric and have a water temperature in the heating season that is always above about 45-50°F, reverse cycle heat may be right for you. | Because no raw water is needed, you may winterize your cooling system and close your through hull ball valve. |

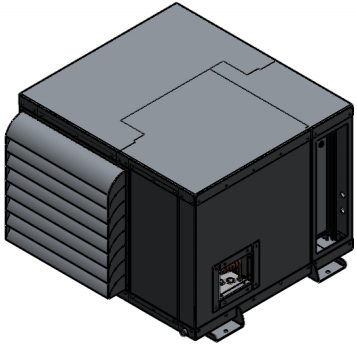

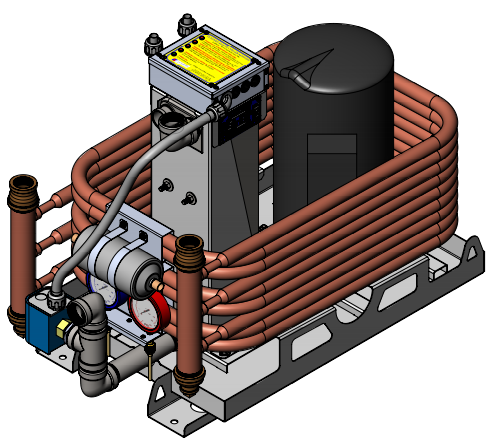

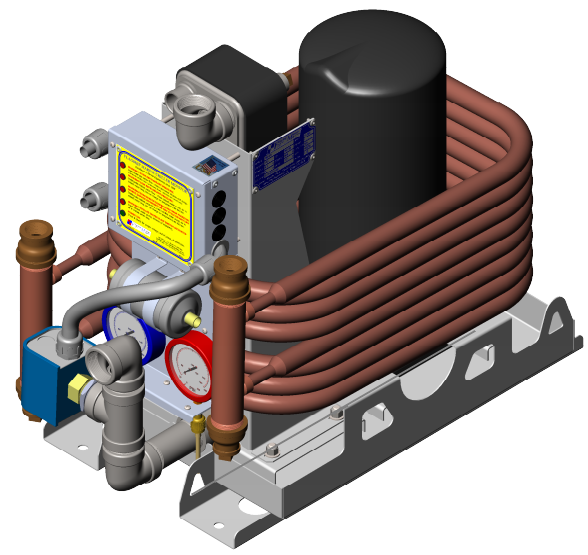

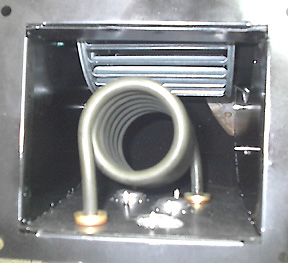

The elements are in line with the air flow and create negligible back pressure. Never restrict the suction side of a centrifugal blower or pump, conversely, you may restrict the discharge side with relative impunity. Our low-temperature elements are safely mounted inside the discharge throat of the blower motor, only a fraction of an inch away from the squirrel cage – it never gets red hot, and therefore doesn’t “burn” the air.

Three “fail-safe” temperature limit switches are within inches of this element, making our time proven system the safest available.

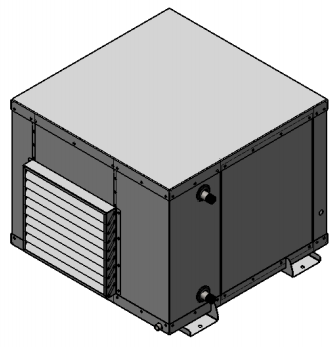

A “straight cool” marine A/C with electric heat is much more simple and trouble-free. There is no need for a reversing valve that is notorious for sticking, and no need for a heat pump thermostat, or the extra relay, refrigerant tubing and wiring to operate this system. You will be able to heat your boat even in dry dock.

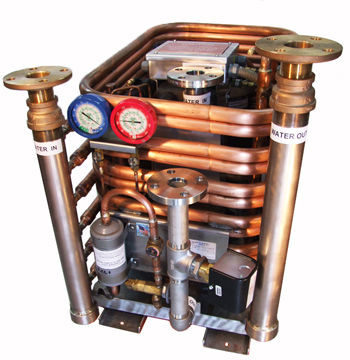

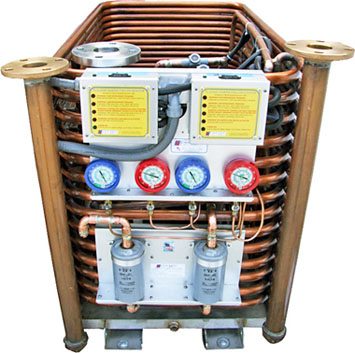

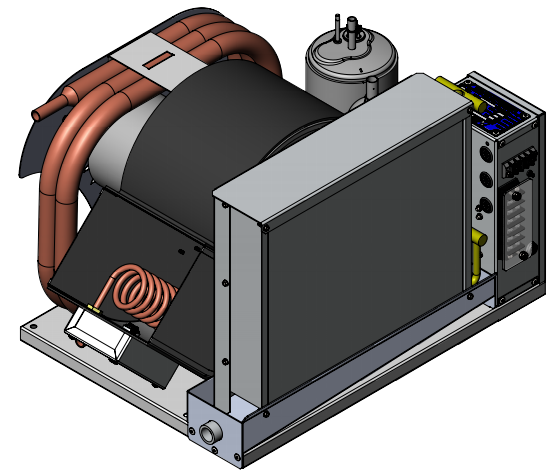

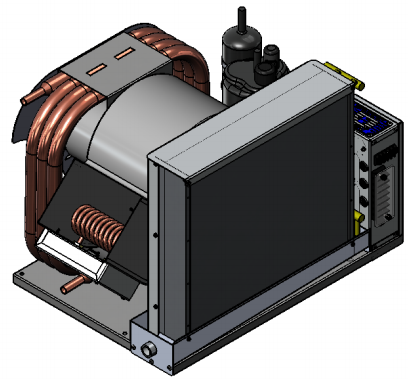

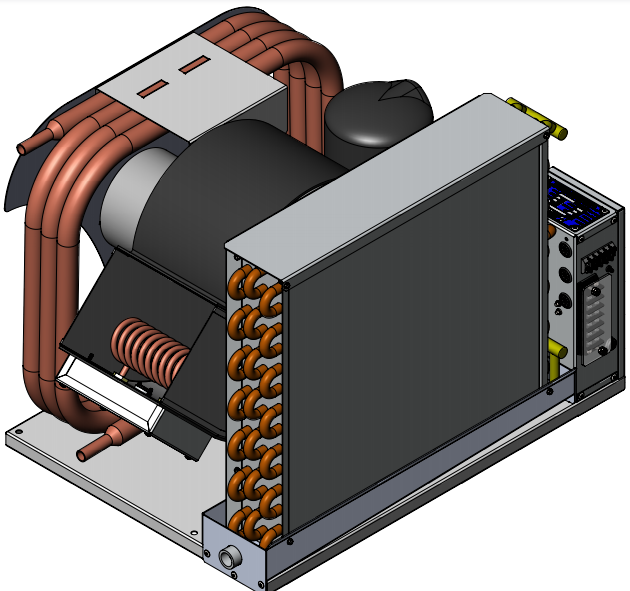

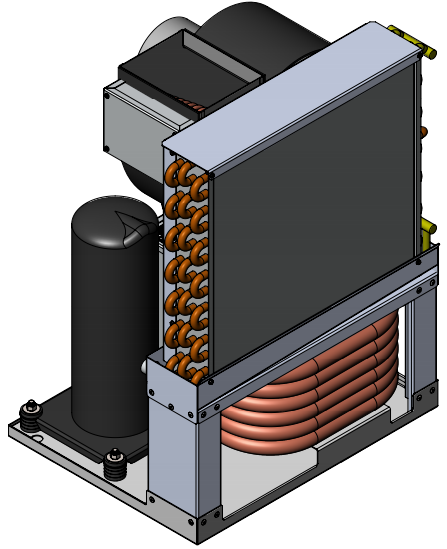

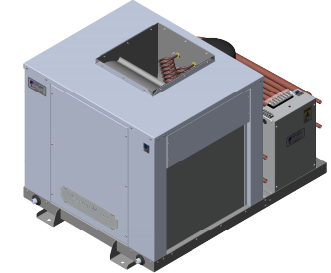

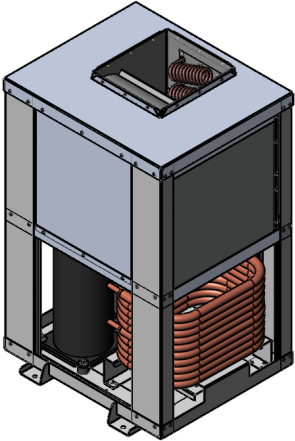

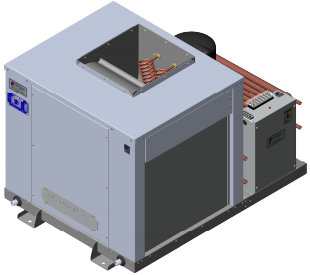

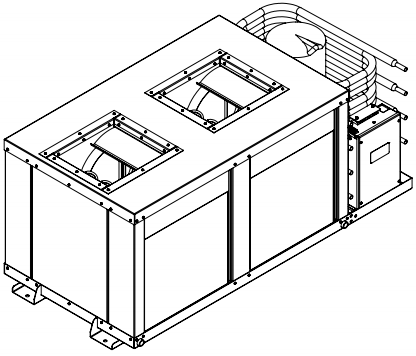

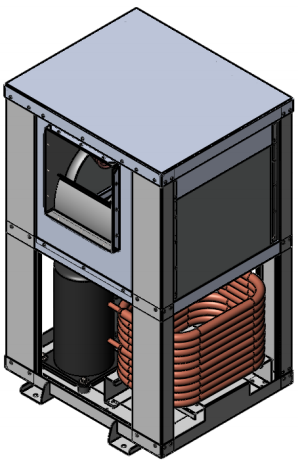

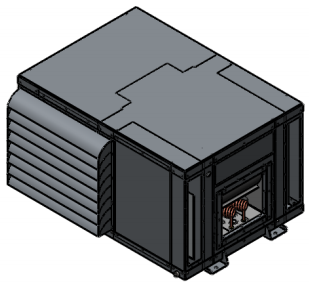

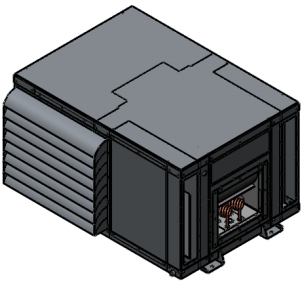

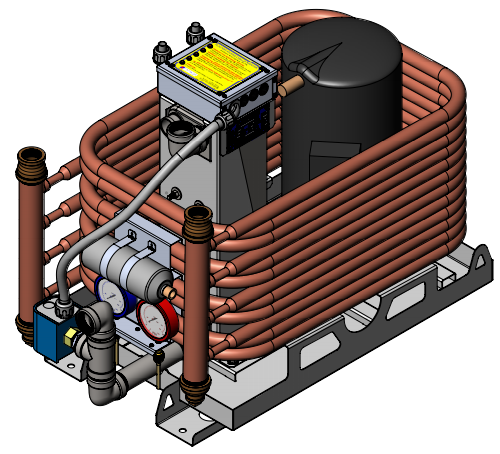

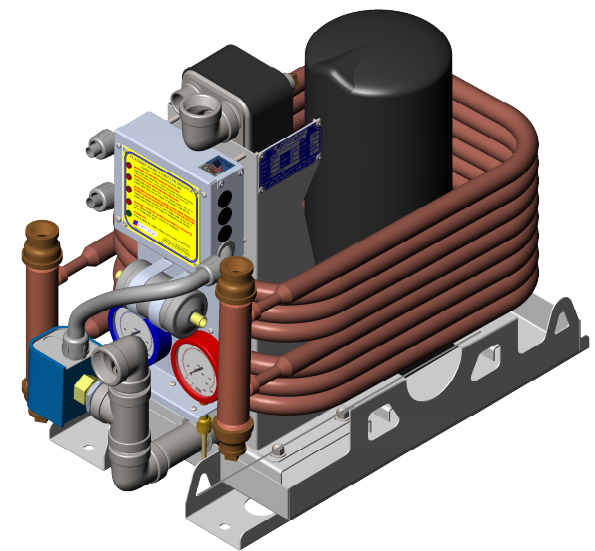

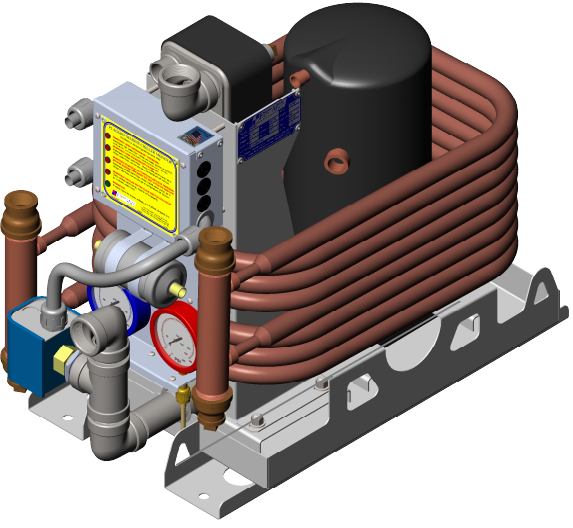

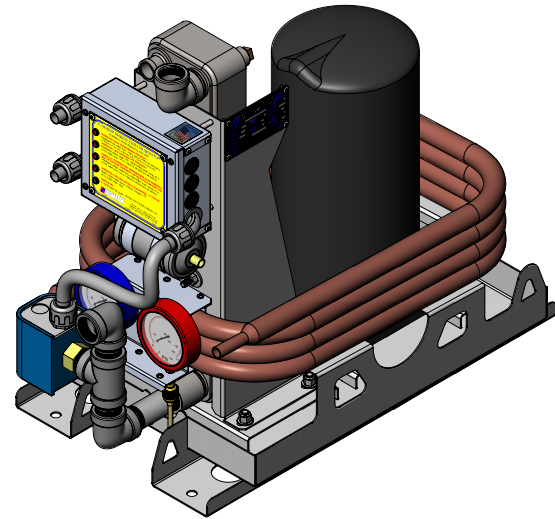

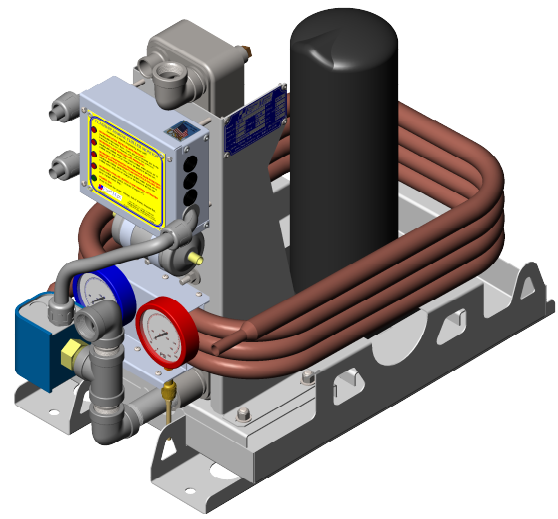

The condenser in a reverse cycle unit in the heat mode will get very cold and possibly develop ice and sweat. This is why most reverse cycle units have the condensers in the horizontal position so that they will not drip on the blower motor, and why most reverse cycle units have a full wet drain pan. Our condensers never get cold and can, therefore, be mounted vertically, over the blower motor. Our drain pan needs only be under the evaporator, making the likelihood of condensate splashing out of the pan in a heavy sea unlikely and keeping the components dry.

Flagship’s incredibly safe, effective and reliable heating systems have been heating the US and Canadian Coast Guard’s survival craft for several years in the most extreme and demanding environmental conditions imaginable – from Alaska, the Great Lakes, and Maine, to the Caribbean and the Gulf of Mexico, since 1995.’

We have thousands of these heating elements in service for many years – they are designed to last decades, not years!