- Home

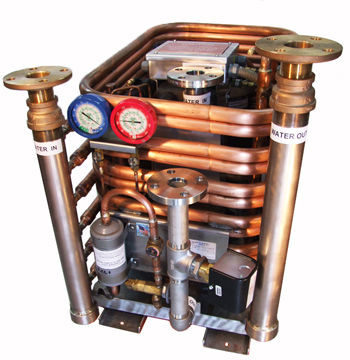

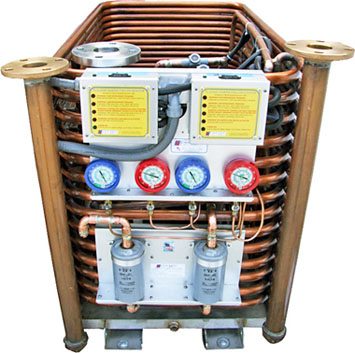

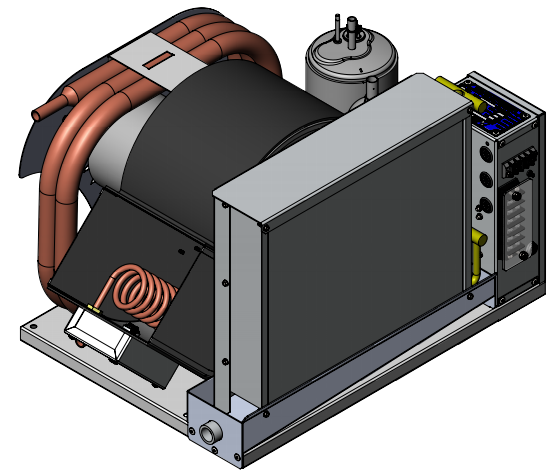

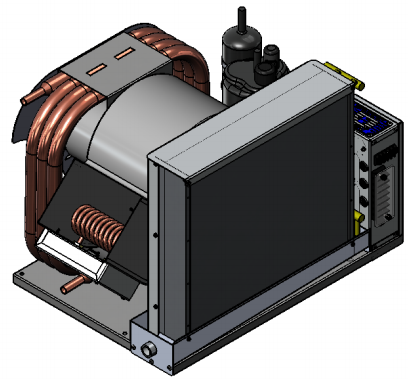

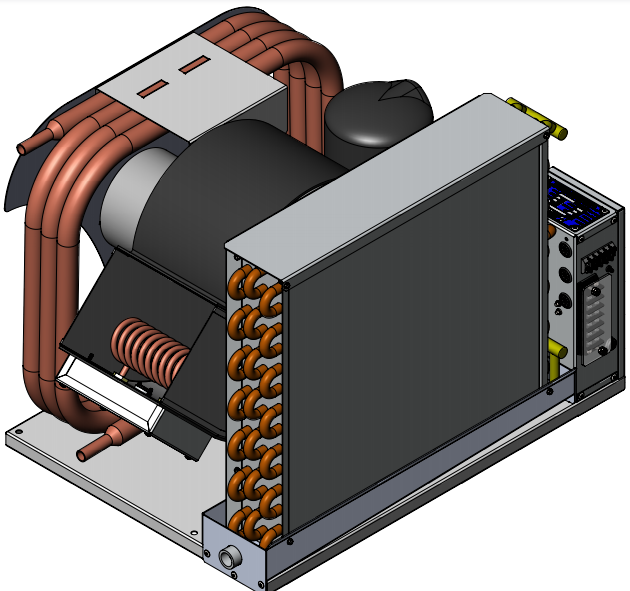

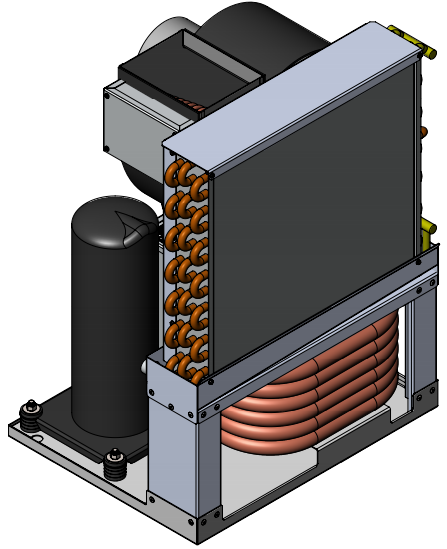

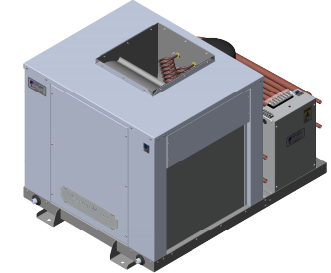

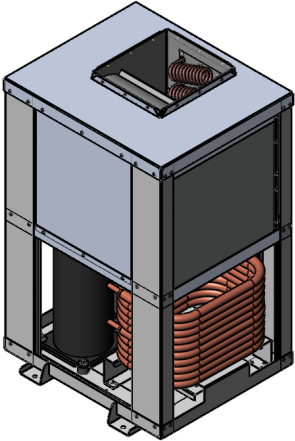

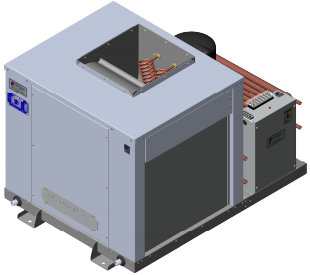

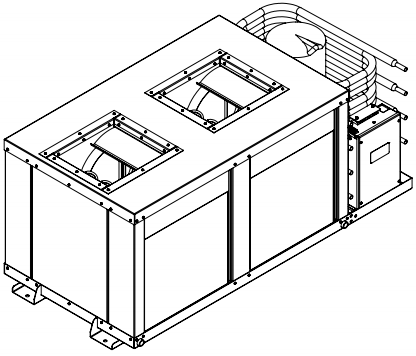

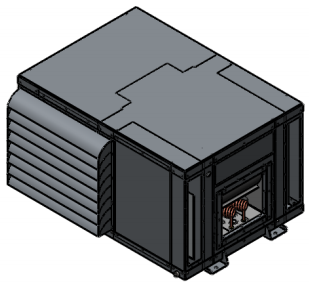

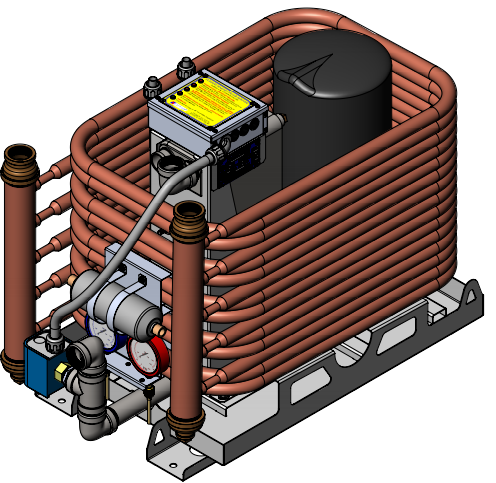

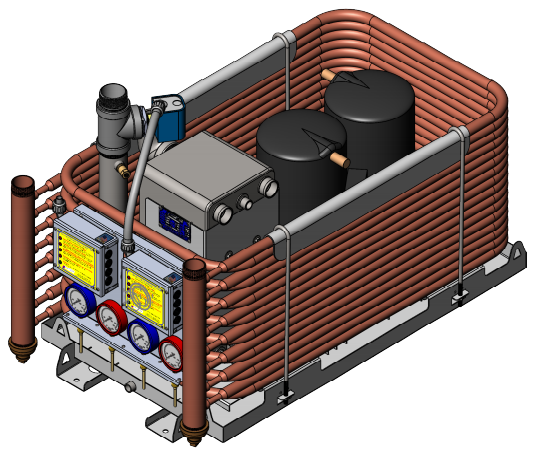

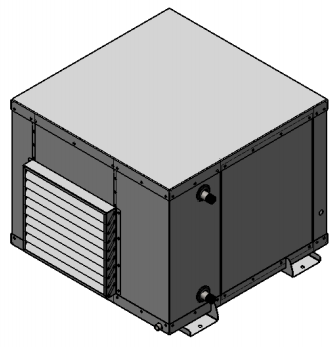

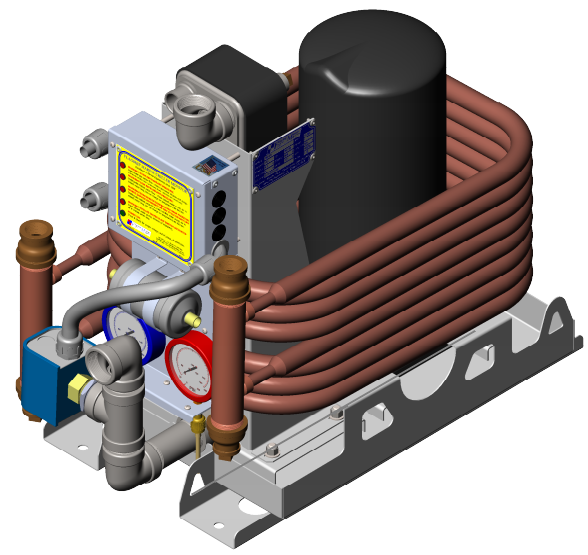

- Marine HVAC Units

- Marine HVAC Parts

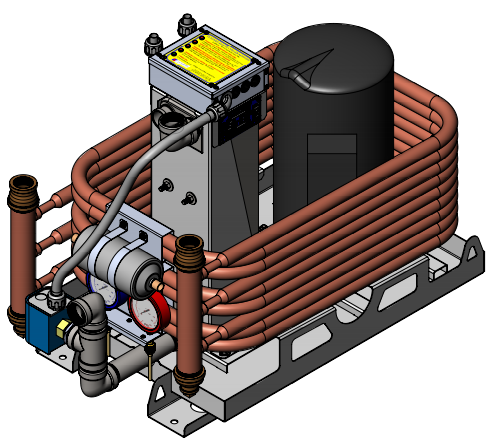

- Pumps

- Technology

- Support

- 5 Things to know before buying a marine air conditioning pump

- Flagship warranty

- How to size your boat

- Installation Do’s and Don’ts

- Manufacture Comparison

- Mini Split Systems

- Multiple unit installations

- Pump manufacture conversion

- Reverse Cycle Heat VS Electric Heat

- Variable Frequency Drives & Digital Scroll Compressors

- About Us

- Contact Us