Mini Split Systems pro's and con's

This fairly new innovation has one variable speed condensing unit supplying refrigerant to up to eight small remote evaporators. This can result in a very significant savings to the end user in certain situations, such as a home, by cooling only the rooms that are occupied.

In a marine application, it’s not typical for air conditioned areas to not be occupied, so these savings are not realized in the marine industry. However, the many detriments of these systems remain and they can be acute in a marine application. It’s no wonder why no marine HVAC manufacturer makes mini split systems. If you do decide to install a residential system on your vessel, you should expect to be replacing the outdoor components quite frequently! Due to the adverse marine environment, you might get a couple of years out of the condensing unit!

In operation when one of the remote evaporators calls for cooling, the slave board in the remote evaporator sends a signal to the motherboard in the condensing unit. This triggers the compressor to ramp up and open the solenoid going to that evaporator to provide refrigerant thus cooling the room.

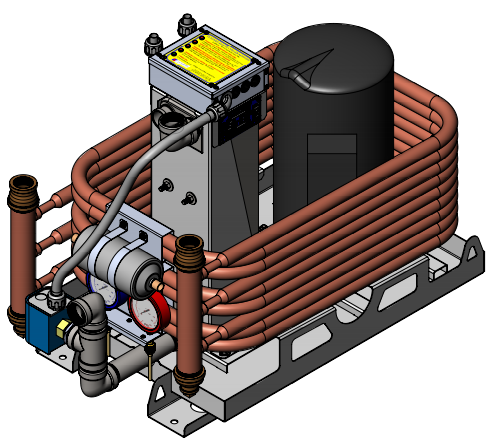

Every remote evaporator requires its own refrigerant lines connecting it to the condenser. On a typical vessel, you will have hundreds of feet of refrigerant lines, half of which are cold return lines that must be insulated. Each evaporator requires separate piping and wiring of the power cable, the refrigerant tubing, the suction tubing, and a condensate drain between itself and the condensing unit. Now imagine all of this buried behind panels, deck heads, and cabinetry. This is reminiscent of the split systems of the past which have fallen out of favor in the marine industry over the years because of the ongoing maintenance and downtime due to relentless refrigerant leaks caused by rotted copper lines and leaking brazed joints that are so hard to locate.

Imagine the difficulty a technician will have trying to sniff out a leak that could be anywhere along these hundreds of feet of refrigerant lines. At least every 50′ (the length of a roll of copper tubing) you have a brazed joint, and these lines are buried in the structure of the moving/flexing vessel. With a SINGLE leak, the ENTIRE system is down!

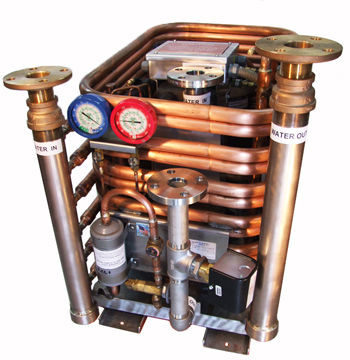

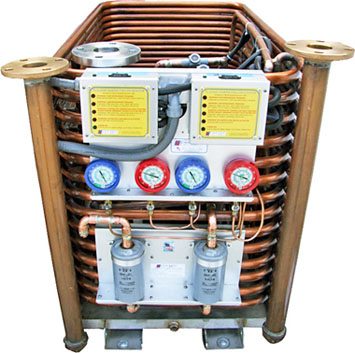

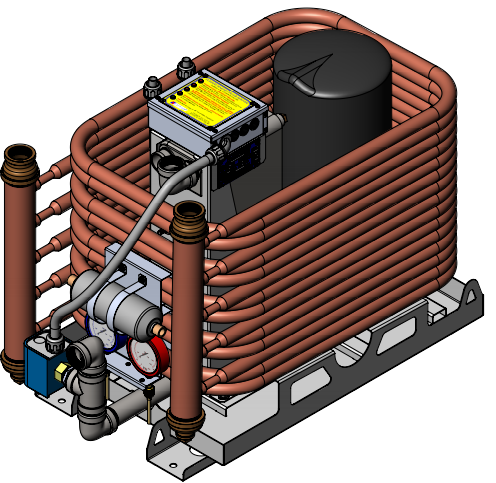

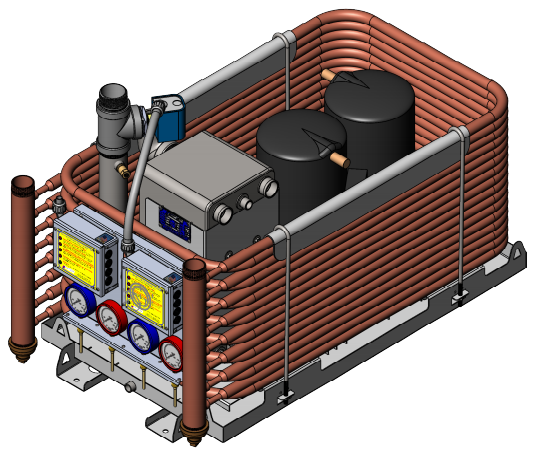

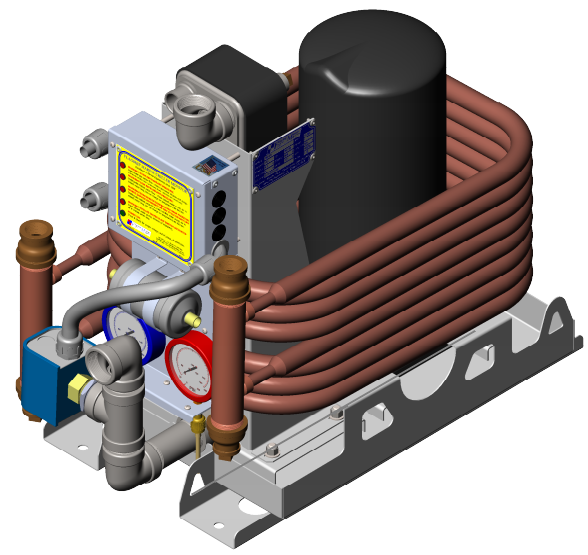

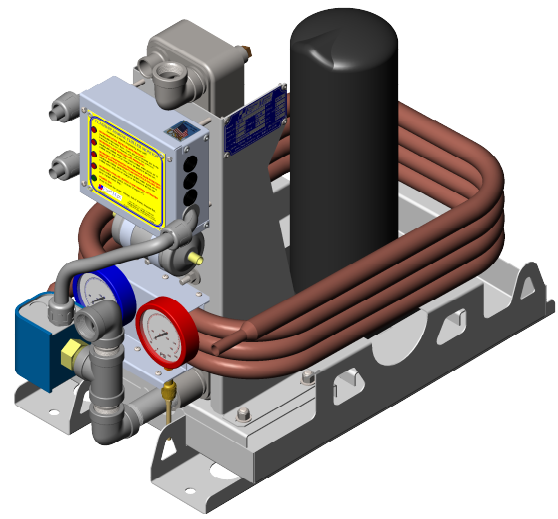

As proven time and time again there is “no free lunch” with thermodynamics, so the tonnage is the same resulting in no weight or current savings. The only way to save weight is to use thin sheet metal and other inferior components. If the load is 12 tons you will need twelve tons of cooling regardless of the type of system – you will NOT be running a mini split system at 25% capacity at high noon with a hundred people on board! It will be 100%! A chiller system works the same way so at 10PM your Flagship Marine chiller might be running ten minutes/hour, so the total current consumption will be basically the same with any system.

The condensate is oftentimes problematic because it can be difficult finding a sensible means of running a condensate drain from every remote wet evaporator. Sometimes it’s easier to run dry ducting rather than install wet evaporators.

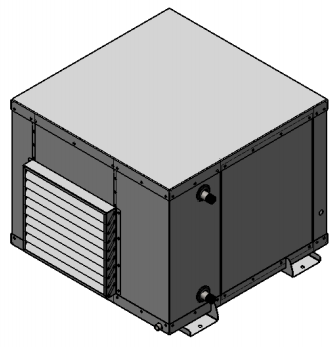

In conclusion, we believe a chiller system in these applications is much more desirable, and especially with Flagship Marine equipment, you will have ZERO expensive/proprietary printed boards that can cost you a small fortune over the years. Mini splits are the MOST complicated/complex systems electronically. Printed circuit boards and naked copper tubing don’t do well on a moving, flexing vessel in a marine environment!