Important Things To Know

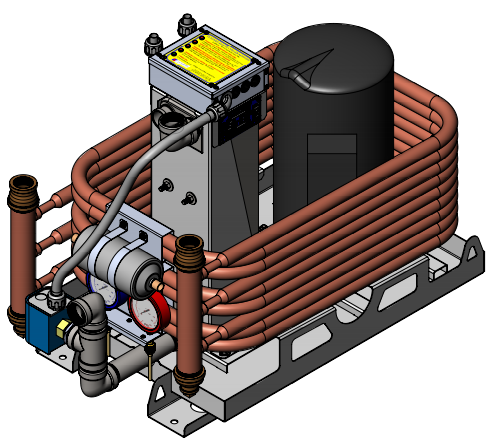

If replacing a pump with the exact same pump model and the unit or units were operating correctly, you may not be interested in this information. However, for those of us who find that the previous owner did not always do things correctly, this may help. Most marine A/C pumps are not self-priming they are known as flooded volute pumps. They must be mounted below the waterline and above the strainer to prevent air locks.

- How many BTU’s are you needing to cool?

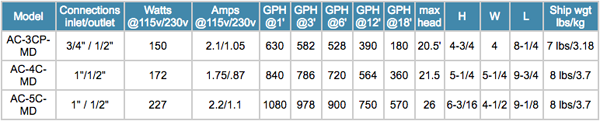

For every 12,000 BTU’s (1 Ton) you need 3 gallons of Seawater a minute delivered to the A/C unit. So, a 16,000 BTU unit would need 4 gallons a minute or 240 gallons per hour.

- What is the maximum rise in the discharge hose?

This starts our baseline measurement. Start by measuring the height distance. Between pump and the unit say 3 feet. Now add in about 6 inches per gradual bend and 1 foot for a hard 90-degree turn. Let’s say we have 3 bends and one ninety. Or 2.8 feet rounding off we see we have 6 foot of head. A Tee fitting will add 1.5 feet of head pressure Using this chart as an example you can see we have lost some flow because of this.

- What is the size of the thru-hull and suction line?

You want to match or go one size higher than the inlet to your pump with your suction hose. Never ever starve or reduce the suction side of a pump below the size of the volute intake size.

- What is the size of the pump discharge?

The discharge side of a pump does not mean that is the size of the hose or tubing you will want to run to your units. Size of the hose effects flow: you can increase flow by increasing the pipe size of your trunk line and then reducing the main trunk line at the unit itself.

- What voltage is the pump and at what hertz does it operate on?

220 volts hertz is important as most pumps run 20 percent less efficient than they would at 60 hertz. With that information, you should be able to make the correct decision