Tired of $600.00, $700.00, $800.00 repairs to replace “the board”?

As with any industry, there are some companies that are willing to sell their primary products at a very small profit because they know eventually they will sell you replacement parts that are ONLY available from them at a very great profit.

Many extended warranties are virtually worthless because of the fine print – how can you defend yourself against an alleged “low voltage episode,” a “possible lightning strike” or a “voltage spike”?

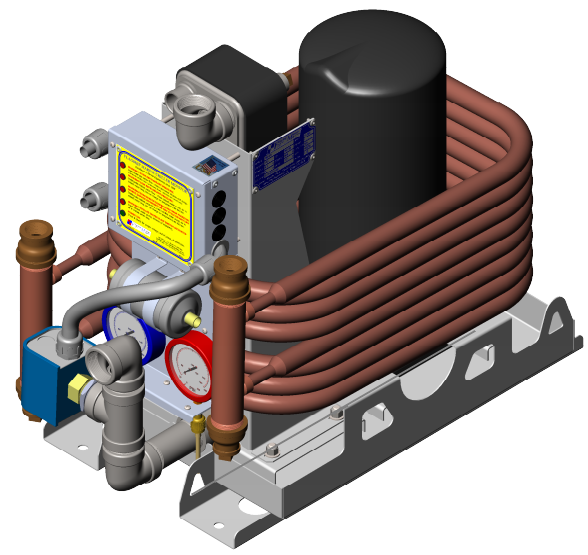

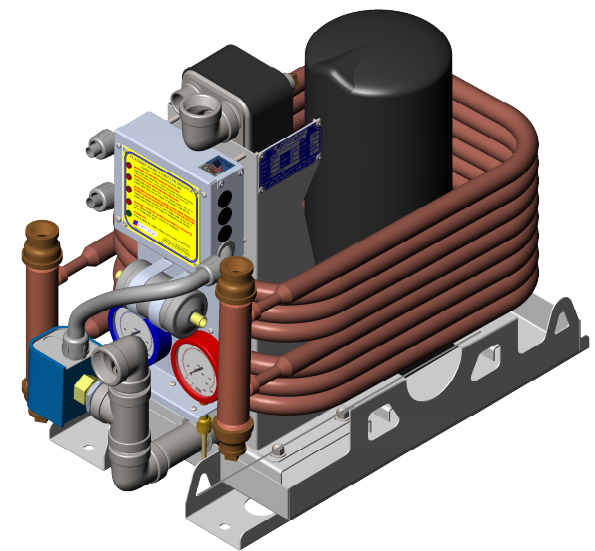

At Flagship Marine, we don’t incorporate ANY expensive proprietary electrical components, every electrical component is individually replaceable, most cost in the teens, and the most expensive electrical component is the digital control, a replacement for which is a mere $64.95 (without the faceplate that is reusable).

At Flagship Marine, we primarily use over-the-counter, non-proprietary components. You can always replace a single $19.95 relay, a $20.00 time delay module, a $14.00 transformer, a feature-filled digital control for only $64.95, etc. We believe the consumer will ultimately benefit from this practice and become repeat customers of Flagship Marine.

We believe the following comparisons will convince you that Flagship Marine is the best value on the market today:

| Flagship Marine Features | Our Competitors |

|---|---|

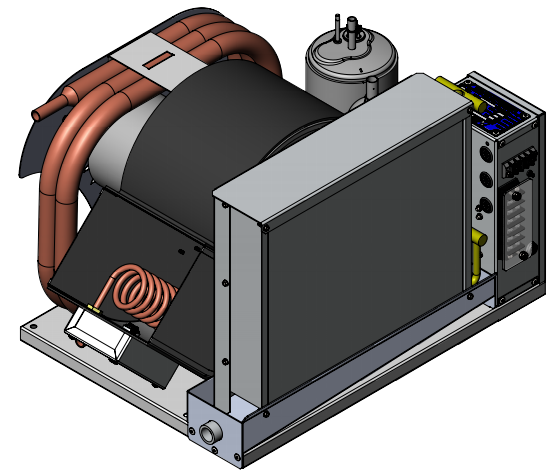

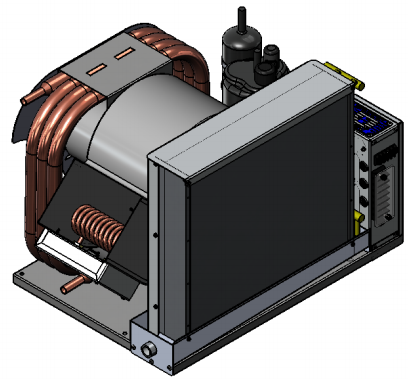

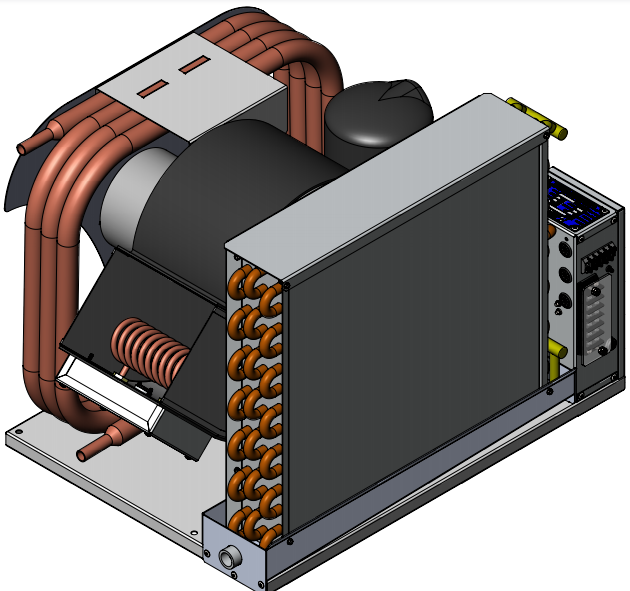

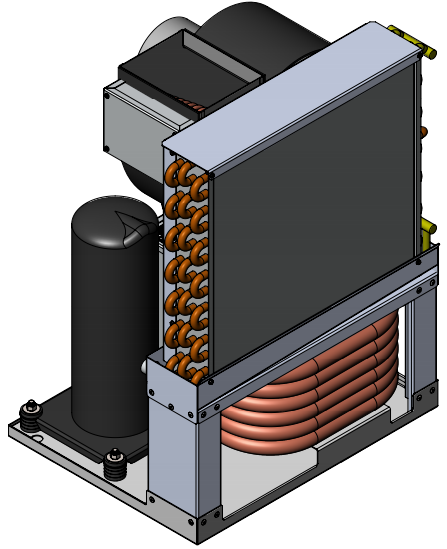

| Stainless steel chassis | Many of our competitors use painted steel that will rust. |

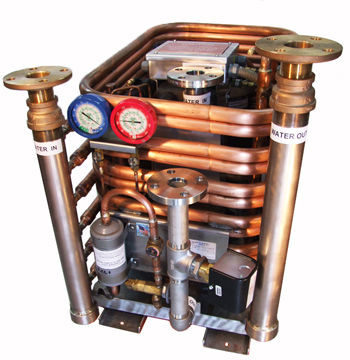

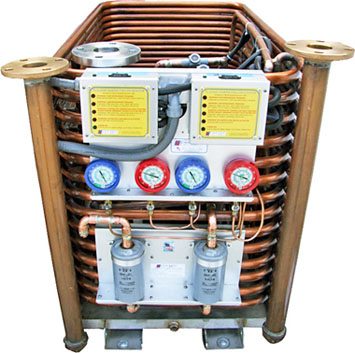

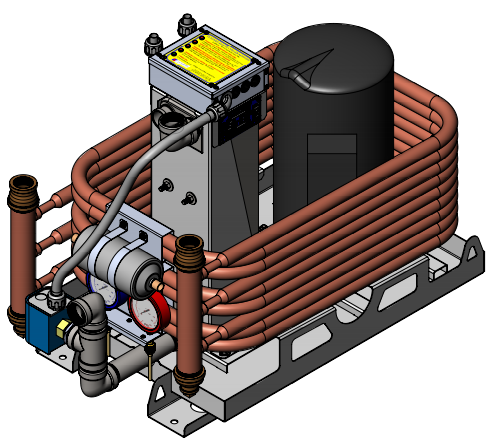

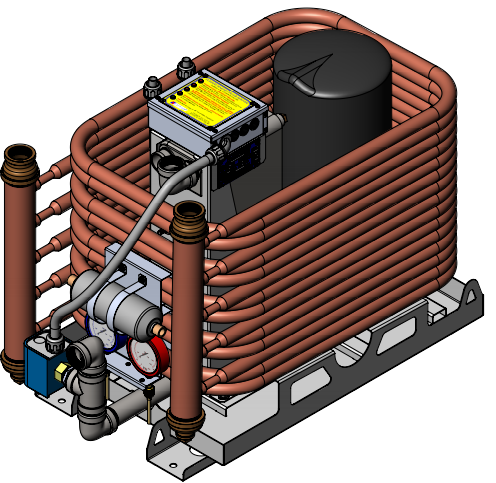

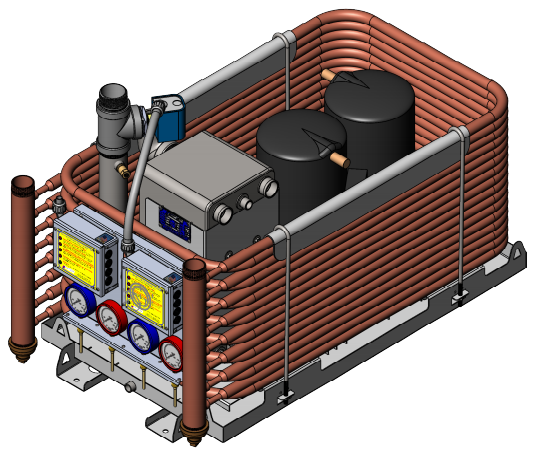

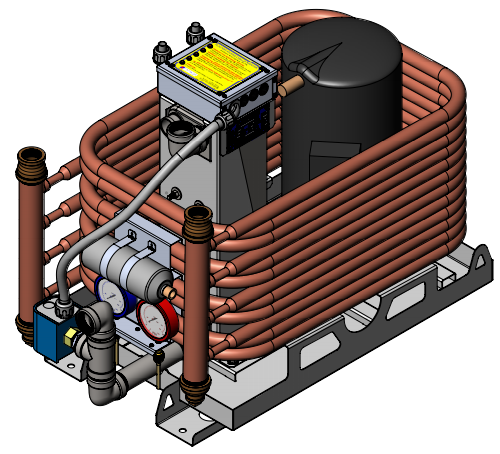

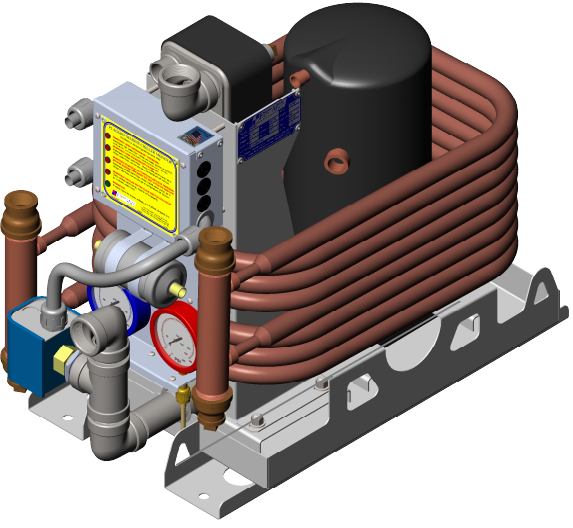

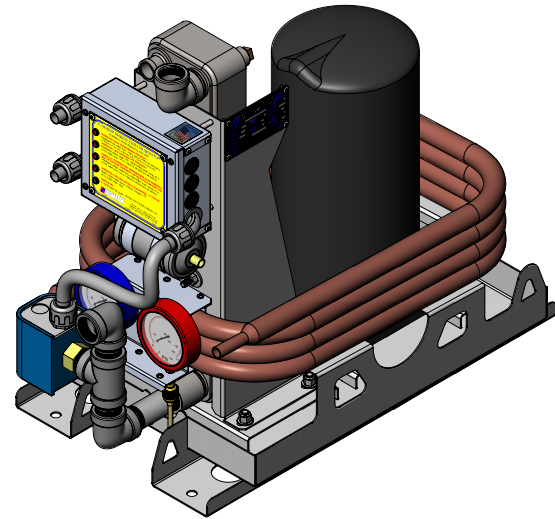

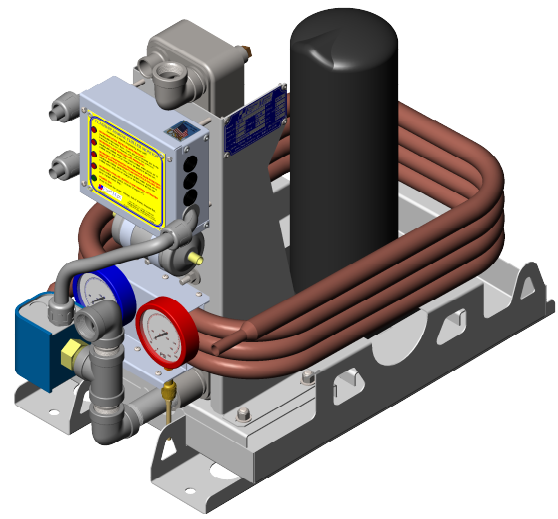

| Copper/Cupronickle condenser.s | Many of our competitors use painted Steel/Cupronickle condensers that can rust. |

| Dry drain pan – compressor is mounted on a dry chassis (except low profile and units over 48,000BTUs). | Many of our competitors’ compressors sit in condensate water and will rust. |

| Simple schematic – a child can follow our wiring diagrams. | Need rocket scientist to follow schematic. |

| Independent electrical components – you can replace a single relay, a time delay, a transformer, etc. – usually inexpensive over-the-counter components – you are not "married" to us for very expensive printed circuit boards. | Many of our competitors incorporate very expensive, sophisticated, unique and complicated printed circuit boardsthat are seldom repairable and ONLY available from the manufacturer. |

| Typical HVAC wiring – no specialized marine HVAC training necessary – We believe in the philosophy – "If I can’t fix it, it doesn’t belong on my boat". | You will usually need a highly trained marine HVAC technician, specifically trained for the unique and complicated marine system to make repairs. |

| Slick inner condenser tube – much less likely to become clogged and easier to clean but must be longer to have the same surface area. | Many of our competitors use enhanced, twisted, rifled or grooved tubes that increases the surface area and reduces the tube length, however it is more easily plugged and harder to clean |

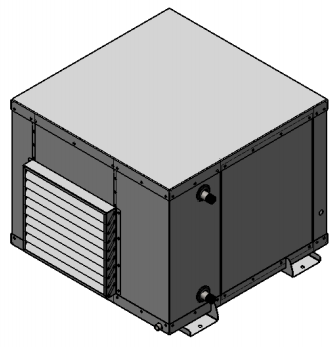

| Insulated blower motor and evaporator chamber for quiet operation while eliminating component sweating. | Some of our competitors have uninsulated blower motors and evaporator chambers resulting in unnecessary noise and sweating. |

| Multiple safety controls including: built in chassis circuit breaker, high refrigerant pressure switch, compressor thermal overload switch, tinned marine oil resistant wire, triple heater safety switches, etc. | Most of our competitors do not have all of these safety features. |

| Simple digital control – in a pinch you can cross all of the digital control wires except the white for cool or yellow for heat. Any four wire thermostat will operate any Flagship Marine unit. | Many of our competitors have very expensive, sophisticated, unique and complicated controls that are almost never serviceable and ONLY available from the manufacturer. |

| "Hard start" capacitors are standard on all Flagship Marine units over 9,000BTUs – this greatly reduces the start up surge when the compressor starts (the larger scroll compressors do not need this option- they start effortlessly by design). | Most of our competitors do not have this feature as standard equipment and will impose a significant charge for a "soft start" or "hard start" kit. |

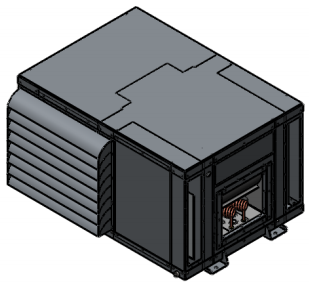

| Our dimensions are accurate! | Some of our competitors post the chassis dimensions which sometimes do NOT include protrusions such as the blower motor. |

| Self draining condenser – Our vertically mounted condensers self drain when the pump stops, making winterization a breeze and eliminating the marine growth on the inside of the condenser tube. | Many of our competitors have horizontally mounted condensers that need to be winterized with anti-freeze and hold water when the pump is not running. |

| Attractive and affordable ($89.95) flush mounted digital control is powered by internal batteries that isolate it from voltage spikes – the thermistor actually measures the stainless steel faceplate temperature. | Most of our competitors have either very expensive, sophisticated, unique and complicated digital controls or surface mounted "domestic" thermostats that would typically be found in a house (not very salty!) |

| Flagship Marine heating systems are simple and work anywhere – whether your boat is in the water or out of the water, regardless of the climate and water temperature. In the heat mode the only moving part is the blower motor, extending the other components’ service life. | Many of our competitors use reverse cycle heat which requires the pump and compressor to run when making heat. These systems simply do not work without a resistive heat backup in colder climates, and we believe are unnecessarily complicated. |

| No sales tax – except units shipped to a Florida address. | Many of our competitors are obligated to collect sales tax in all states. |