On-Site Design Engineer

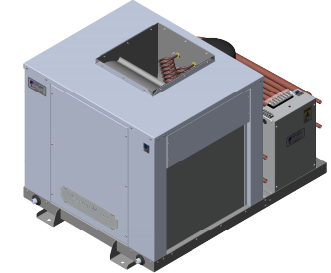

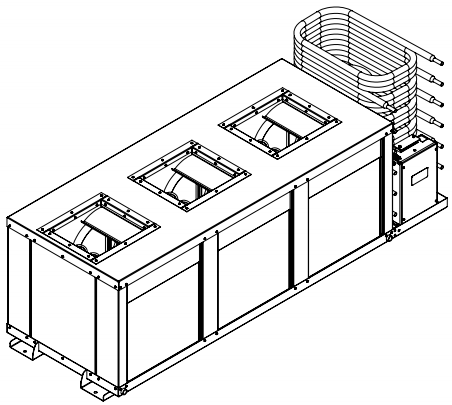

Military Quality Chilled Water Systems

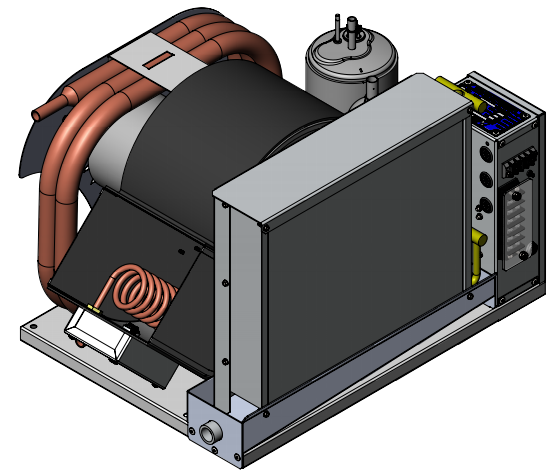

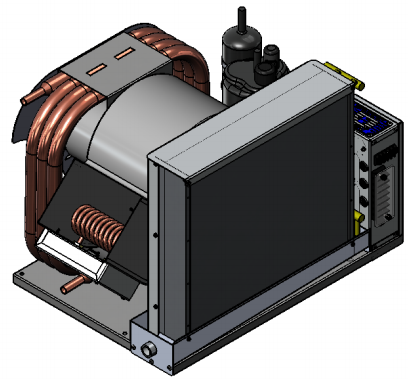

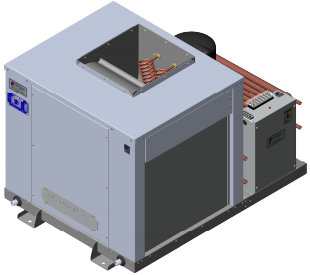

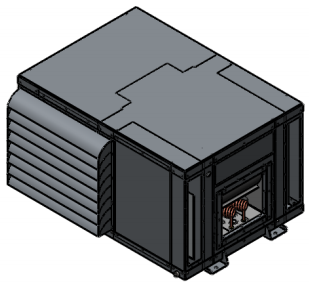

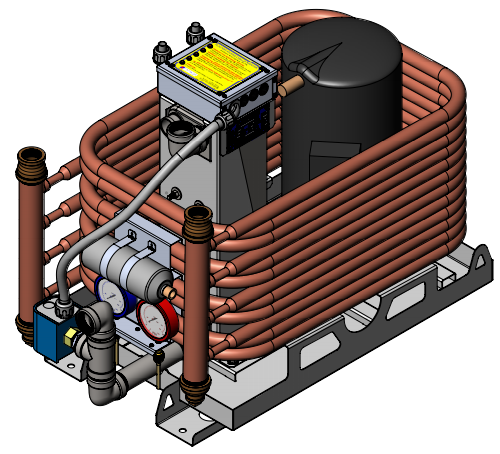

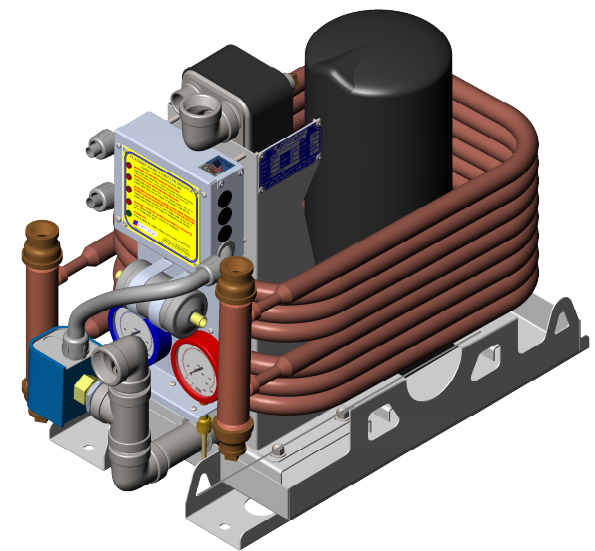

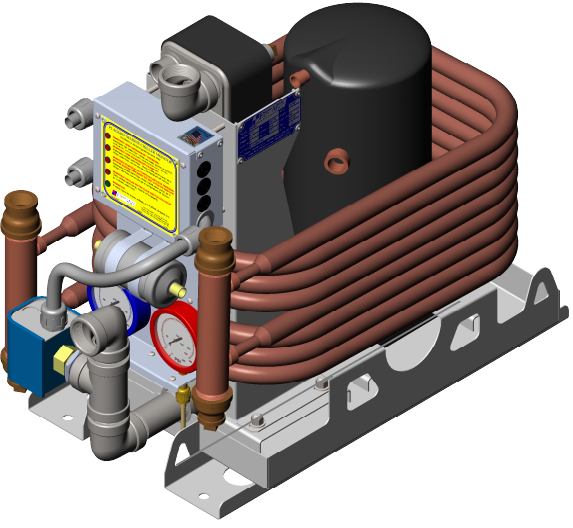

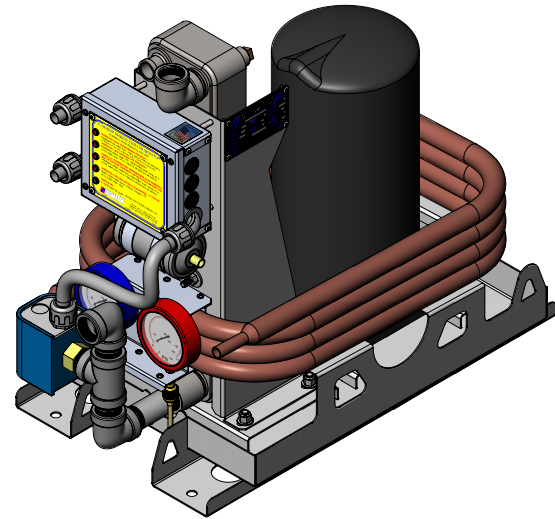

Metal Components Are CNC Cut

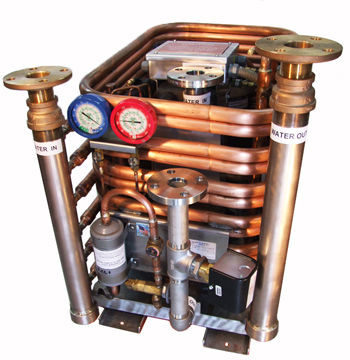

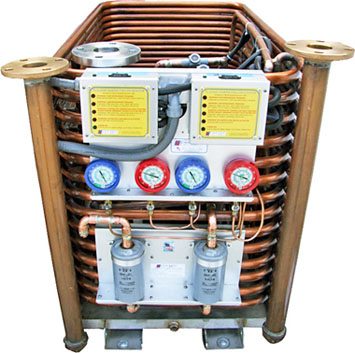

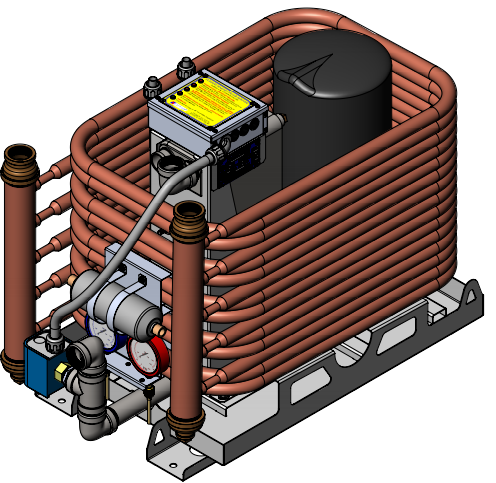

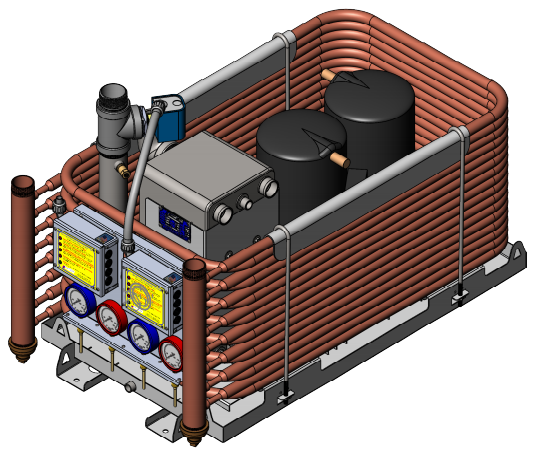

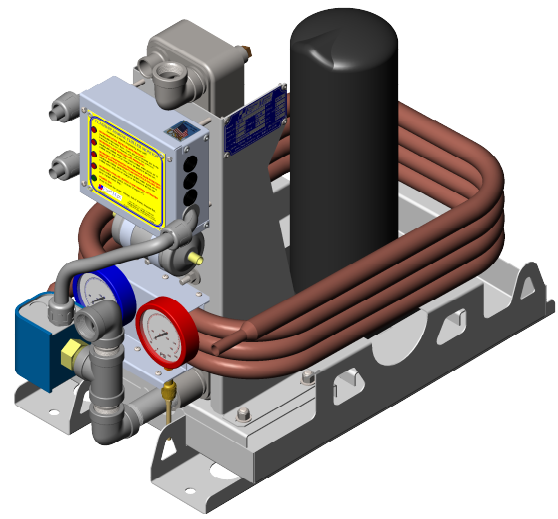

All sheet metal components are CNC cut and fabricated with CNC brakes and fastened with SS rivets and PEM inserts. Condenser tube to manifold connections are made with precision machined 90/10.

CuNi (Copper-Nickel) socolets that are TIG welded to the schedule 80 90/10 CuNi nipple with a monel alloy and brazed to the condenser tubes to ensure many years of trouble-free service. This configuration meets all MilSpec and ABYC requirements. Naked connections aren’t nearly as durable and fail to meet those standards. For your convenience, all manifolds are fitted with reducing couplers and a 3/4″ drain plugs for winterizing.

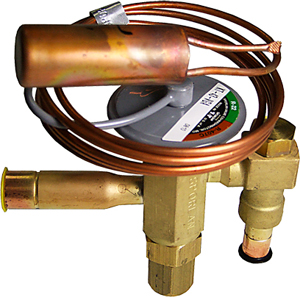

Expansion Valves vs. Capillary Tubes

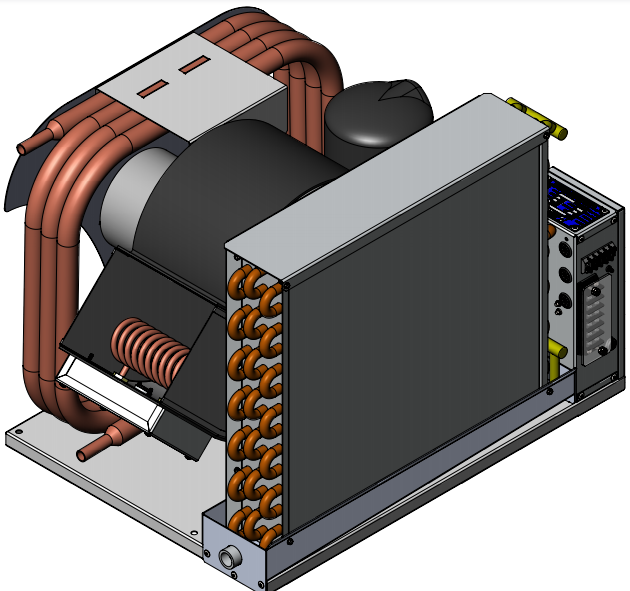

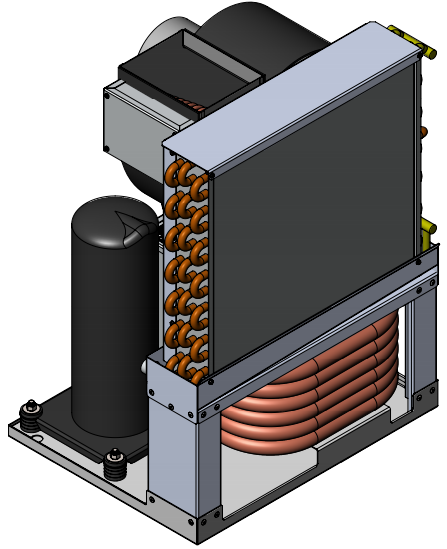

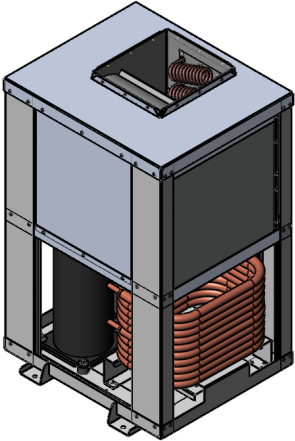

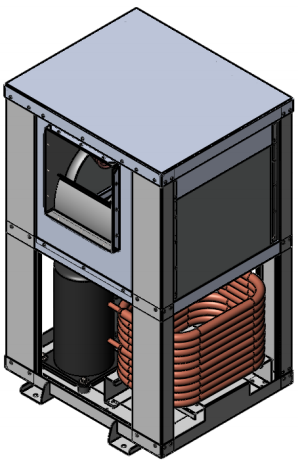

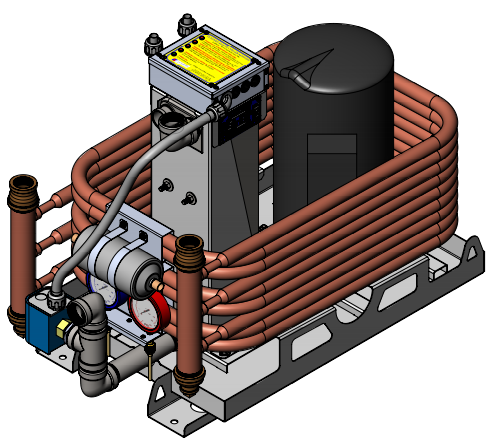

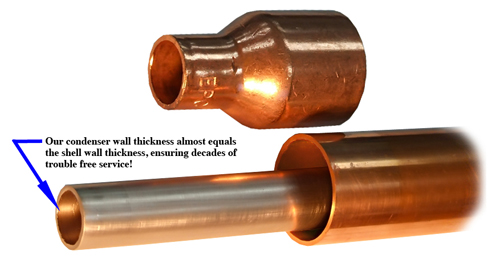

Flagship Marine Units NEVER Have Condenser Failures

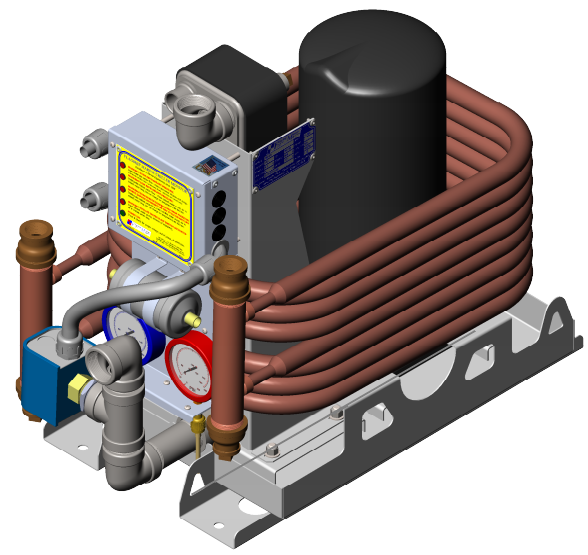

The heart of every marine air conditioner is the condenser—the heat sink to the ocean and the only component the corrosive sea water touches is the inside of the inside tube. Failure of this tube is catastrophic for the entire system. Even extremely corrosive places like the very high salinity of the Red Sea are no problem for Flagship Marine condensers because we use an unusually thick walled 90/10 CuNi (copper-nickel) tube with particular annealment, hardness, and other characteristics.

Titanium Condensers?