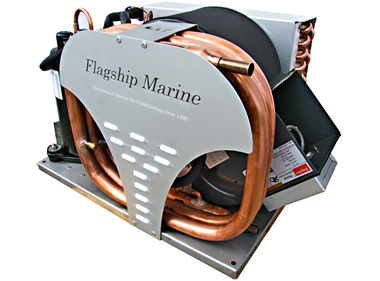

MOST POPULAR SELF-CONTAINED UNITS

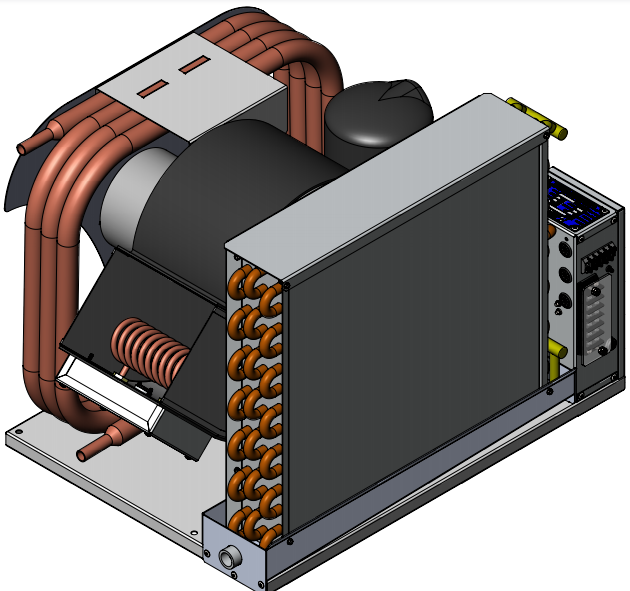

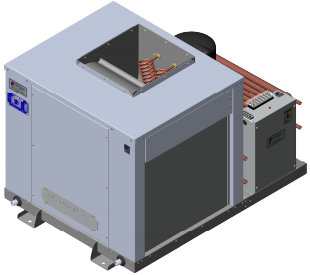

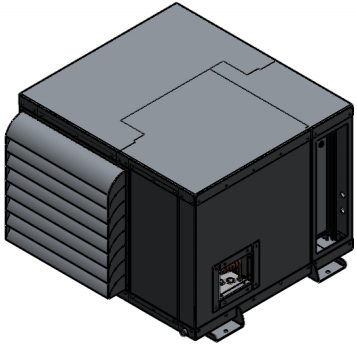

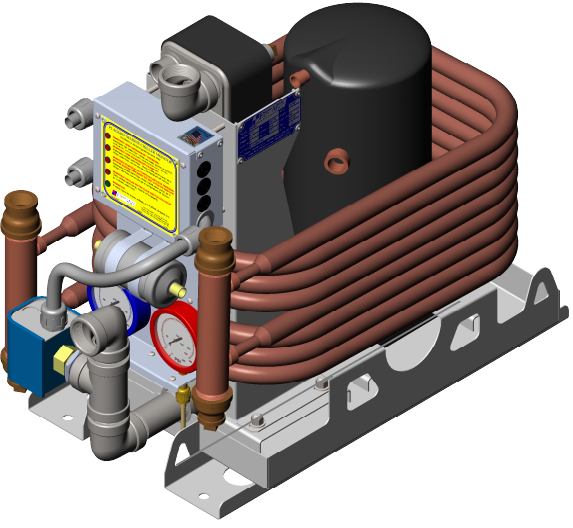

16,000 BTU Unit

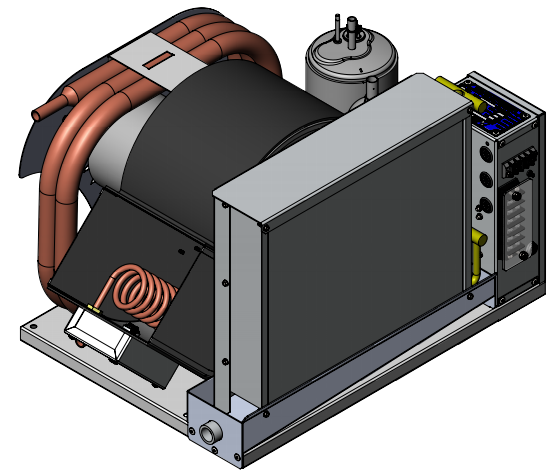

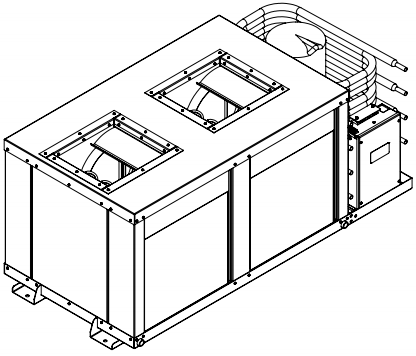

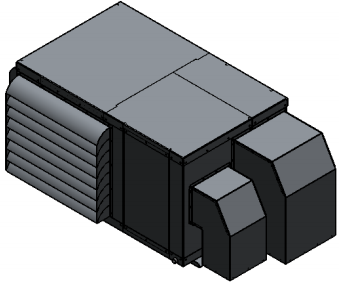

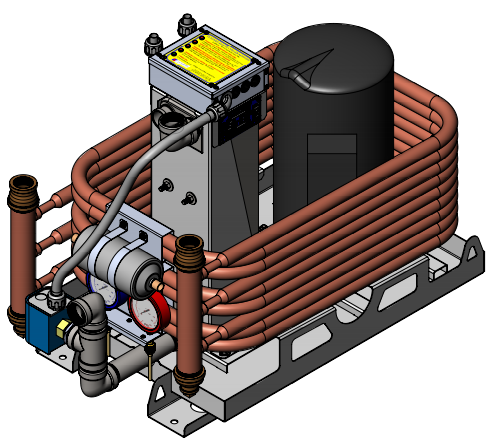

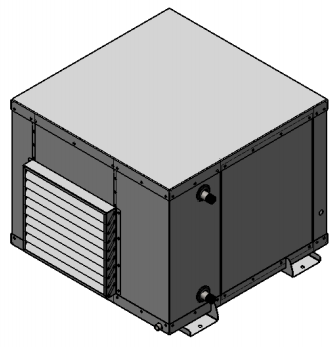

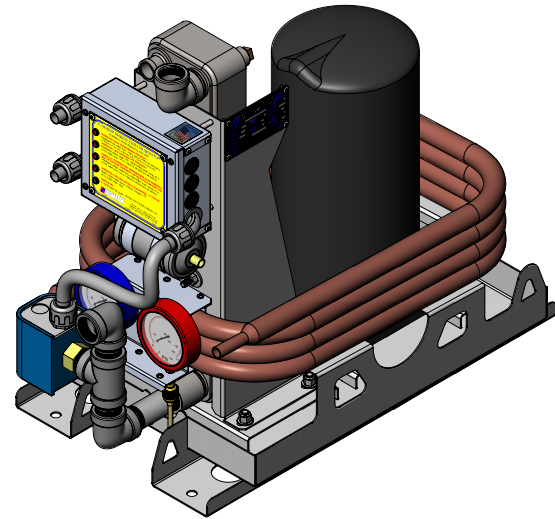

18,500 BTUs Low Profile Unit

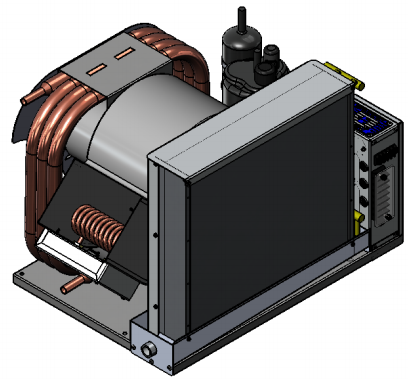

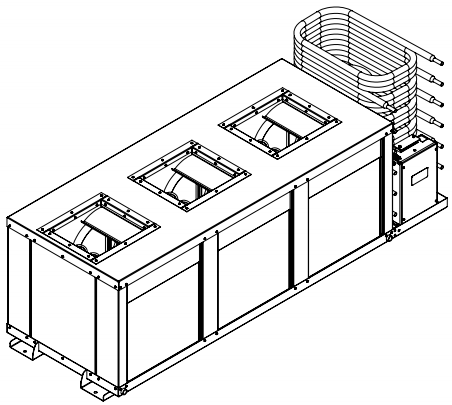

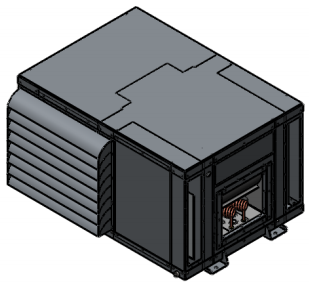

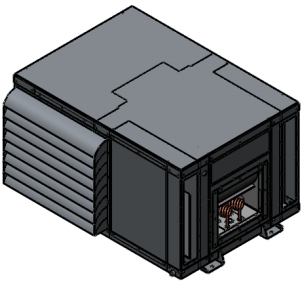

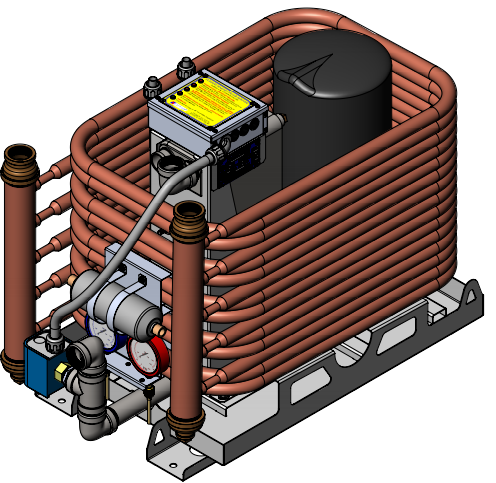

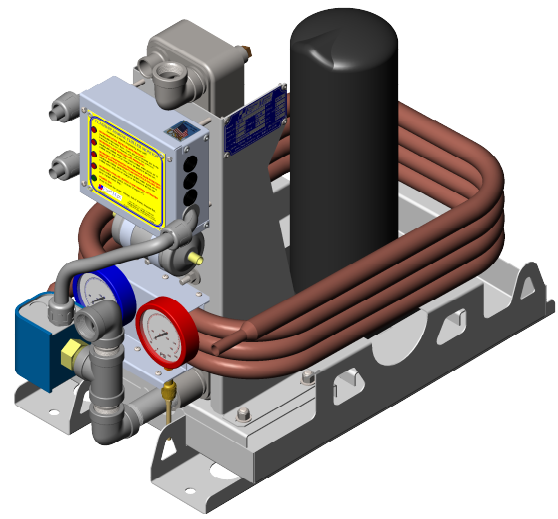

24,000 BTU Unit

Self-Contained Info and Specs

| Model | BTU's | Blower CFM (Cubic ft./min.) | KW of elec. heat | Specs | Length/Width/Height in inches/mm | Amps (cool) 115/230 | Amps (heat) 115/230 | Wgt lbs/kg | Buy Now |

|---|---|---|---|---|---|---|---|---|---|

| FM9R View Image | 9,000 | 273 | 1.7 | Manual & Drawing | 19.6"/13.2"/13.2" 498/336/336 |

8.3/4.0 | 13.9/6.9 | 59/28 | BUY NOW |

| FM12R View Image | 12,000 | 485 | 1.7 | Manual & Drawing | 21.5"/13.6"/12.5" 547/346/318 | 8.9/4.0 | 17.7/8.9 | 69/32 | BUY NOW |

| FM16R View Image | 16,500 | 555 | 2.0 | Manual & Drawing | 21.5"/14.6"/13.5" 547/371/343 | 11.3/5.7 | 18.1/9.0 | 77/35 | BUY NOW |

| FM18R View Image | 18,000 | 555 | 2.0 | Manual & Drawing | 20"/14.6"/13.5" 508/371/343 | 12.3/6.1 | 18.1/9.0 | 82/38 | BUY NOW |

| FM18RLP View Image | 18,000 | 555 | 2.0 | Manual & Drawing | 24"/17"/10.5" 610/432/267 | 12.9/6.4 | 18.1/9.0 | 113/52 | BUY NOW |

| FM18.5R View Image | 18,500 | 805 | 2.2 | Manual & Drawing | 25.5"/16"/14.5" 648/407/369 | 16.2/7.7 | 19.4/9.7 | 90/41 | BUY NOW |

| FM20R View Image | 20,000 | 990 | 2.2 | Manual & Drawing | 25.1"/17.5"/16" 638/445/407 | 17.1/7.7 | 20.3/10.2 | 95/44 | BUY NOW |

| FM24R View Image | 24,000 | 990 | 4.0 | Manual & Drawing | 28.1"/18.6"/17.5" 714/473/445 | 10.2-230V | 20.1-230V | 118/54 | BUY NOW |

| FM36S View Image | 36,000 | 1202 | 4.0 | Manual & Drawing | 24.75"/17.25"/19.0" 629/439/483 | 15.8-230V | 20.1-230V | 138/63 | Buy Now |

| FM36S-V View Image | 36,000 | 1202 | 4.0 | Manual & Drawing | 21.0"/17.0"/29.0" 534/432/737 | 15.8-230V | 20.1-230V | 140/64 | INQUIRE |

| FM48S View Image | 48,000 | 2553 | 6.0 | Manual & Drawing | 39.0"/28.0"/26.0" 991/712/661 | 23.0-230V | 28.0-230V | 210/96 | INQUIRE |

| FM48S-V View Image | 48,000 | 2553 | 6.0 | Manual & Drawing | 26.0"/26.0"/46.0" 660/660/1168 | 23.0-230V | 28.0-230V | 230/105 | INQUIRE |

| FM60S View Image | 60,000 | 2553 | 8.0 | Manual & Drawing | 40.0"/28.0"/26.0" 1016/712/661 | 26.7-230V | 37.0-230V | 230/105 | INQUIRE |

| FM60S-V View Image | 60,000 | 2100 | 8.0 | Manual & Drawing | 23.0"/26.0"/46.0" 585/661/1169 | 26.7-230V | 37.0-230V | 230/105 | INQUIRE |

| FM72S View Image | 72,000 | 2553 | 10.0 | Manual & Drawing | 40.0"/28.0"/26.0" 1016/712/660 | 28.7-230V | 37.0-230V | 245/112 | INQUIRE |

| FM96S-H View Image | 96,000 | 5106 | 12.0 | Manual & Drawing | 64.75"/28.0"/26.13" 1645/712/664 | 17.3-230/3V | 26.6-230/3V | 345/157 | INQUIRE |

| FM96S-V View Image | 96,000 | 3200 | 12.0 | Manual & Drawing | 28.0"/28.0"/60.0" 712/712/1524 | 17.3-230/3V | 26.6-230/3V | 345/157 | INQUIRE |

| FM120S-H View Image | 120,000 | 5106 | 16.0 | Manual & Drawing | 64.75"/28.0"/26.13" 1645/712/664 | 28.8-230/3V | 42.9-230/3V | 410/186 | INQUIRE |

| FM120S-V View Image | 120,000 | 3600 | 16.0 | Manual & Drawing | 23.0"/26"/80.0" 585/661/2032 | 28.8-230/3V | 42.9-230/3V | 410/186 | INQUIRE |

| FM180S-H View Image | 180,000 | 7659 | 24.0 | Manual & Drawing | 87.5"/28.0"/33.25" 2223/712/845 | 30.3-230/3V | 44.9-230/3V | 630/286 | INQUIRE |

| FM180S-V View Image | 180,000 | 4800 | 24.0 | Manual & Drawing | 60.0"/26.5"/60.0" 1524/674/1524 | 30.3-230/3V | 44.9-230/3V | 630/286 | INQUIRE |

- The larger units usually have a single 12″ duct or 3-4 6″ ducts – we will supply whatever your particular application requires at no additional charge.

- Our aluminum discharge plenums attach directly to the discharge flange of the blower motor, making attaching the ducts a simple task: add about 6″ to the length of the unit for a side discharge unit or 6″ to its’ height for a top discharge unit. (about 8″ for units larger than 20,000 BTUs)

- One ton of cooling =12,000 BTUs/hour. One BTU is the amount of thermal energy required to raise the temperature of one pound of water one degree F. One calorie is the amount of thermal energy required to raise the temperature of one cubic centimeter of water 1°C. Units’ BTUs are rated in BTUs/hour of continuous operation under ideal conditions.

FOR LARGER APPLICATIONS

with limited space.

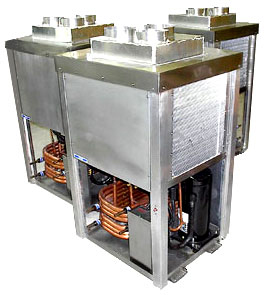

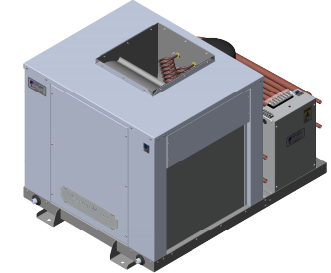

60,000 BTU Self-Contained

These incredibly compact 60,000 BTU units have a tiny 24″ x 27″ footprint and are only 43″ high. They really pack a punch – enough horsepower for 660 square ft. each!

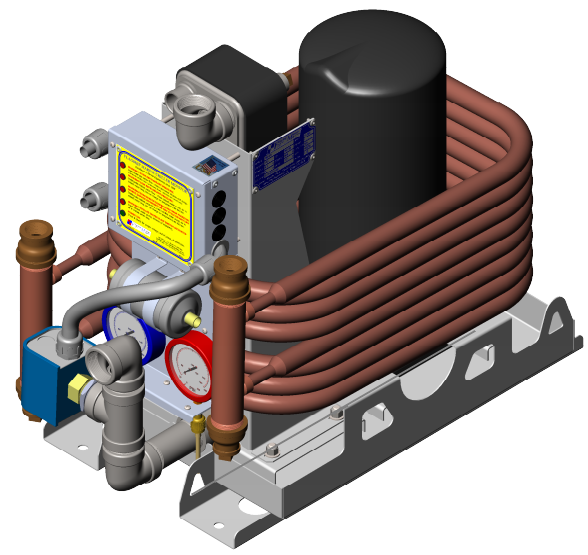

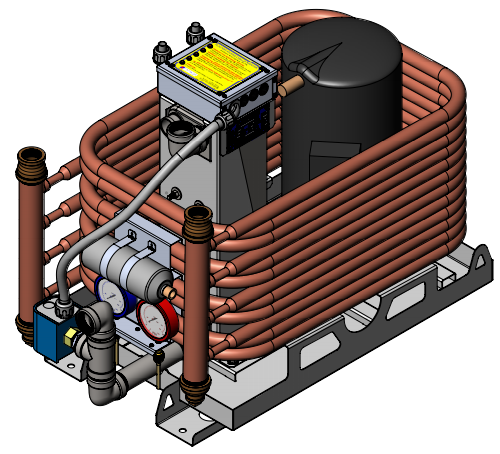

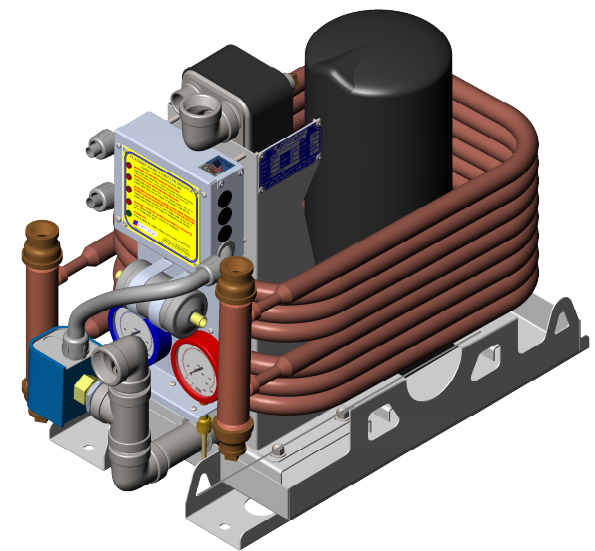

Completely self-contained, these quiet and powerful units need only a power supply line, 15 GPM of seawater (or freshwater with a keel cooler or heat exchanger) and a condensate drain.

On a ship, four of these units will cool and heat an incredible 30′ x 90′ area! Huge savings can be reaped in initial equipment expense, installation and maintenance expense – all while benefiting from redundancy. Two seamen can swap out a unit in minutes in the highly unlikely event of a failure.

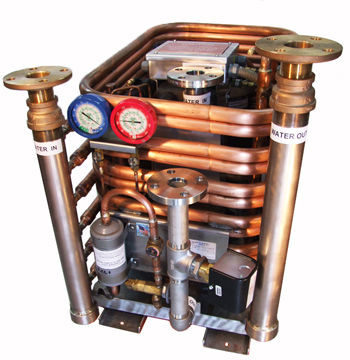

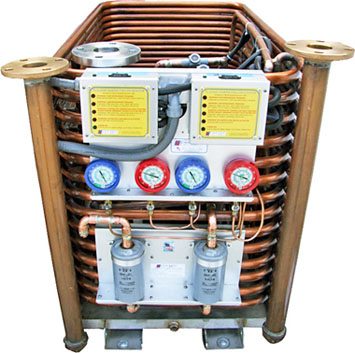

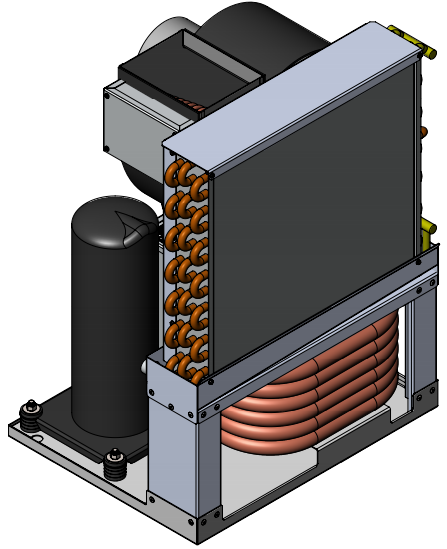

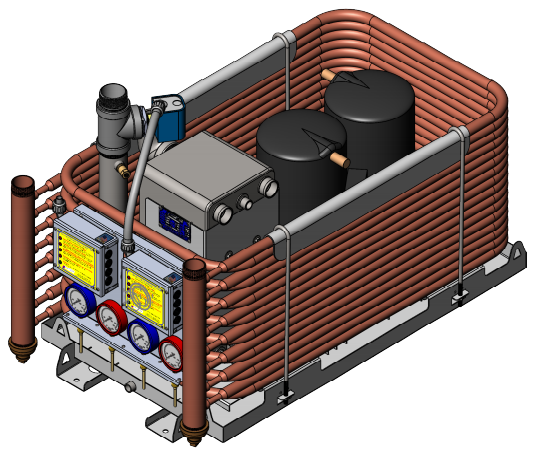

96,000 BTU Self-Contained

This 8 ton (96,000 BTU) unit pumps out more than 5,000 CFM of air conditioned air with two blowers, four evaporators and a nine ton condenser assembly, which results in a low compressor head pressure and amp draw.

Each blower is fitted with 3-6″ collars (many configurations available) for ease of ducting. The single Copeland scroll compressor is staged to start a few seconds after the blowers to minimize the start up surge, even though with a scroll compressor the start up surge is very minimal. Optional condenser manifolds result in a single sea water in and out connection, and the optional refrigerant gauge package lets you monitor the operating conditions of the unit immediately.

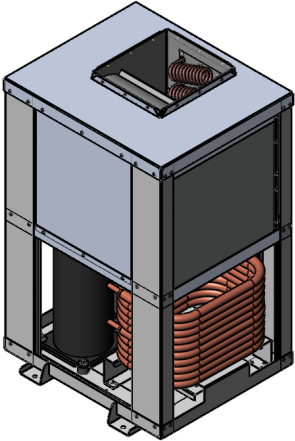

180,000 BTU Self-Contained

This 15 ton (180,000 BTU) unit pumps out more than 7,500 CFM of air conditioned air with three blowers, six evaporators and a huge condenser assembly, which results in a low compressor head pressure and amp draw. Each blower is fitted with a 12″ collar for ease of ducting. The single Copeland scroll compressor is staged to start a few seconds after the blowers to minimize the start up surge, even though with a scroll compressor the start up surge is very minimal. Optional condenser manifolds result in a single sea water in and out connection, and the optional refrigerant gauge package lets you monitor the operating conditions of the unit immediately.

Highest Quality Plus Simplicity of Design

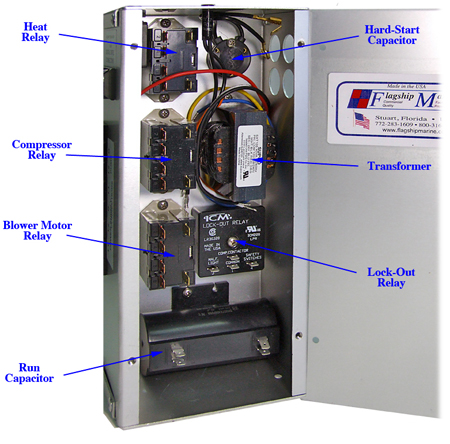

No expensive proprietary printed circuit boards.

What sets Flagship Marine apart from our competition is our belief in the KISS principle (Keep It Simple, Stupid). This has guided our component selection and design emphasis for many years. We brag that even a child can follow our schematics!

As you can see below, the Flagship Marine electric control box has the highest quality over-the-counter components, and it is extremely easy to diagnose and repair a problem.

The most expensive component in this box is less than $28.00! No extremely expensive, proprietary printed circuit boards, and no need for a specifically trained technician! Most problems can be diagnosed and repaired with a voltmeter and a screwdriver!

With Flagship there are no expensive proprietary printed circuit boards. No highly trained technician needed, typically a voltmeter and a screwdriver is all that is needed to make most repairs!

Clearly Labeled Terminal Strip Connections

Clearly labeled terminal strip connections for the power supply, pump and digital control make wiring the system a cinch!

It’s a simple matter to bypass the power supply terminal block and hard wire if you wish to.

This is a convenience item that you may or may not want to use.

Note on the top of the box the internal circuit breaker and red LED that will light when the unit trips on high pressure should you have a sea water blockage or bad pump.

There are several layers of protection built into the unit, ensuring many years of service.

The Highest Quality Components

ALL March and Cal Pumps

Flagship Marine stocks the legendary March Manufacturing and Cal Marine pumps in all voltages and sizes, so we have the right pump for you.

Precision Engineered Plenum Kits

Our anodized aluminum, precision engineered plenum kits

allow you to customize a perfect fit for your particular application!

Typical 16,500BTU plenum

Optional teak grills in various sizes

Optional teak grills in various sizes are typically in stock.

LG Compressors

- Unbelievably quiet due to our unique mounting isolator bushings, insulated blower chamber and rotary or scroll compressors - many of our customers have actually mounted our units under their bunk.

- The LG Rotary Compressors have been an industry leader for many years, and are renowned for being incredibly quiet. It's difficult to hear these compressors start, run or stop, even if you are standing right next to it!

- Very easy to start - Soft start capacitors, stratified start up sequence and time delay compressor circuits in combination with our rotary or scroll compressors make our A/C units start effortlessly - our 16,500BTU unit should be on a 25 amp breaker!

- Very low start up surge - The start up surge of these compressors is a fraction of the dinosaur like piston compressors! Millions of these compressors have been used for many years in window units - the piston compressors simply cannot meet the minimum energy efficiency standards.

- Dry drain pans - The rotary and scroll compressors do not sweat and therefore do not sit in their own condensate and rust! All of our single evaporator models (less than 48,000BTUs and the low profile FMAC16PLP) have dry drain pans - there is a small drain pan only under the evaporator!

Exclusive 840 Incoloy Clad Tubular Heating

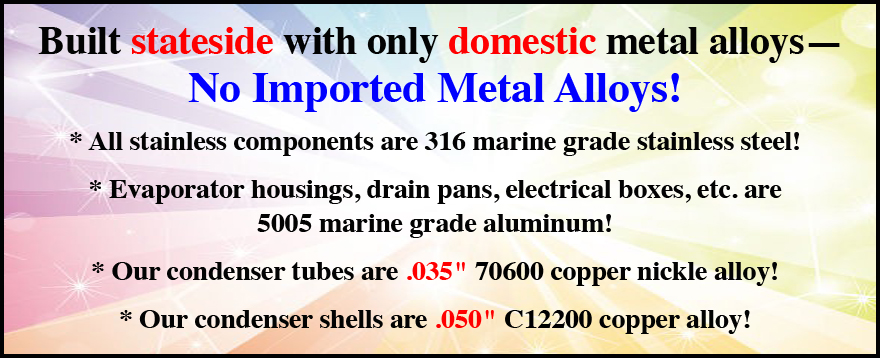

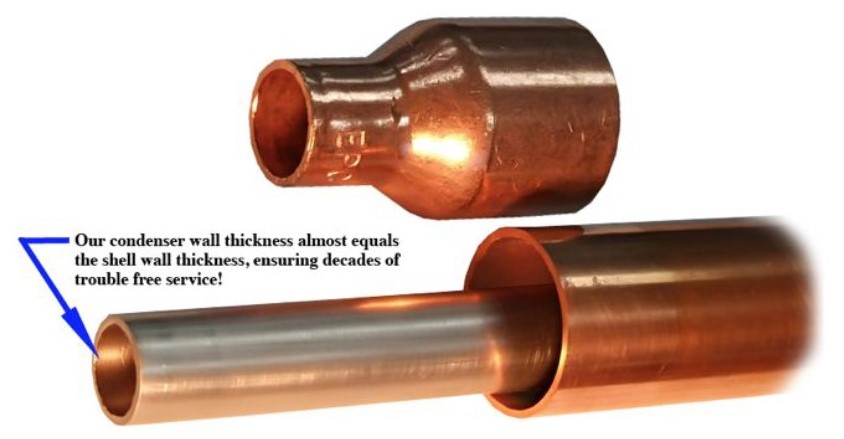

The heart of every marine air conditioner is the condenser—the heat sink to the ocean and the only component the corrosive sea water touches is the inside of the inside tube. Failure of this tube is catastrophic for the entire system. Even extremely corrosive places like the very high salinity of the Red Sea are no problem for Flagship Marine condensers because we use an unusually thick walled 90/10 CuNi (copper nickel) tube with particular annealment, hardness and other characteristics.

Flagship Marine Units NEVER Have Condenser Failures!

Titanium condensers can be appropriate in some marine applications such as in a power plant where the sea water velocity is greater than 7 feet/second CONSTANTLY – 100% OF THE TIME. This velocity is too fast for barnacle larvae to bond to the metal, and once they do it’s too late!

Titanium has zero anti-microbial properties and when the water is dormant marine growth will take hold very quickly. This is why our competitors state condenser cleaning is REQUIRED at least ONCE/YEAR.

Flagship Marine condensers MIGHT need an acid wash every ten years!

The other big problem with Titanium is brazing it to the condenser shell. One of our major competitors is using steel shells that start to rust in a couple of months, the other major competitor uses a copper shell that fails and offers mechanical seals to repair them.

The heart of every marine air conditioner is the condenser – the heat sink to the ocean and the only component the corrosive sea water touches is the inside of the inside tube. Failure of this tube is catastrophic for the entire system.

Even extremely corrosive places like the very high salinity of the Red Sea are no problem for Flagship Marine condensers because we use an unusually thick walled 90/10 CuNi (copper nickel) tube with particular annealment, hardness and other characteristics.

We don’t dramatically shorten our condensers to save money by enhancing this tube: knurling or rifling for example. Our tube is “slick walled” with no thin spots for marine growth to find a foothold. Paper thin condenser tubes dissipate heat very quickly so the condenser tube can be short and inexpensive. We don’t cut corners by doing so. We have full length condensers!

The shorter the condenser, the cheaper it is and the shorter it will last!

Superior Modulation Of The Refrigerant

EXPANSION VALVES VS. CAPILLARY TUBES

All Flagship Marine equipment incorporates expansion valves which adjust the modulation of the refrigerant to match the conditions of sea water, humidity and ambient temperature. This maximizes performance by preventing excessive or inadequate refrigerant head pressures, resulting in more cooling and extended component life!

This is why all new HVAC equipment must now use expansion valves instead of the capillary tubes you may still have in your home air conditioner. We don’t “cut corners” – these cost us about $75-175 each vs a $3.00 cap tube, and on the larger units we use “balanced port” rather than the standard expansion valves which automatically adjust to the amount of refrigerant flowing rather than being a fixed flow and out of balance.

NO Mildew Drain Pans

Flagship Marine Exclusive: Dry Drain Pan

No more mold and mildew starting in your drain pan! We now manufacture sloped aluminum drain pans that are dry so the condensate water doesn’t have a chance to grow mold and mildew.

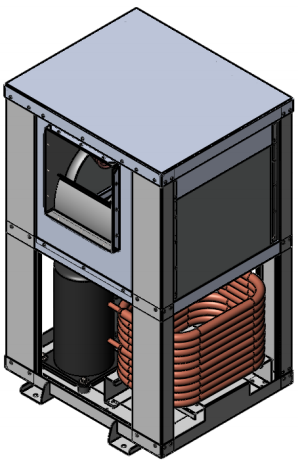

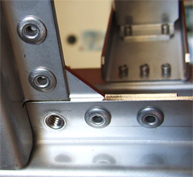

LASER Cut Precision

All sheet metal components are laser cut with aircraft/military quality

All sheet metal components are laser cut with aircraft/military quality tolerances in the ten-thousandths of an inch range as depicted here with the skeleton of an air-cooled chiller. Note the PEM nut inserts and numerous stainless steel rivets that result in a very rigid, strong and exacting structure.

Reduced Voltage Fluctuation

Variable Frequency Drives And Digital Scroll Compressors?

If your vessel is wired single phase or you have marginally sized generators, or if you want to almost completely eliminate voltage fluctuation when compressors start, we can install Variable Frequency Drives (VFDs) in our equipment.

The VFD reduces the start up inrush and will greatly reduce any brown out, generator lag or flickering in your TV when the compressors start.

The typical inrush (millisecond start up amperage) is about 5-7 times the running amps, however with a VFD the compressor frequency slowly ramps up to the 60 HZ speed so the inrush is typically about 1.3 times the running amps. You can also manually program in lower or higher frequencies as well to accomplish running on lower amps or more output at higher amps if you need to, but of course you will lose or gain proportional performance by doing so.

Flagship Marine strives to provide the most simple, trouble free and durable equipment available, and frequency drives are not in keeping with the KISS principal that guides our component selection and design, however there are applications that warrant these excellent products.

No Proprietary Printed Circuit Boards

Flagship's Exclusive Diagnostic Monitors Use Time Tested "Over the Counter" ICM Modules

With Flagship there are no expensive proprietary printed circuit boards. No highly trained technician needed, typically a voltmeter and a screwdriver is all that is needed to make most repairs!

All Flagship Chillers have a low voltage control module with clearly labeled LEDs advising the end user specifically what has tripped the chiller, be it high or low refrigerant pressure, freeze control protection as well as low chilled water flow.

Personalize Your Thermostat!

Our new digital control is programmable or you can override the programs and manually control the temperature.

In addition to a host of features it has a back-lit screen for programming even in the dark.

ANY four wire battery-operated control will operate ANY Flagship Marine Unit